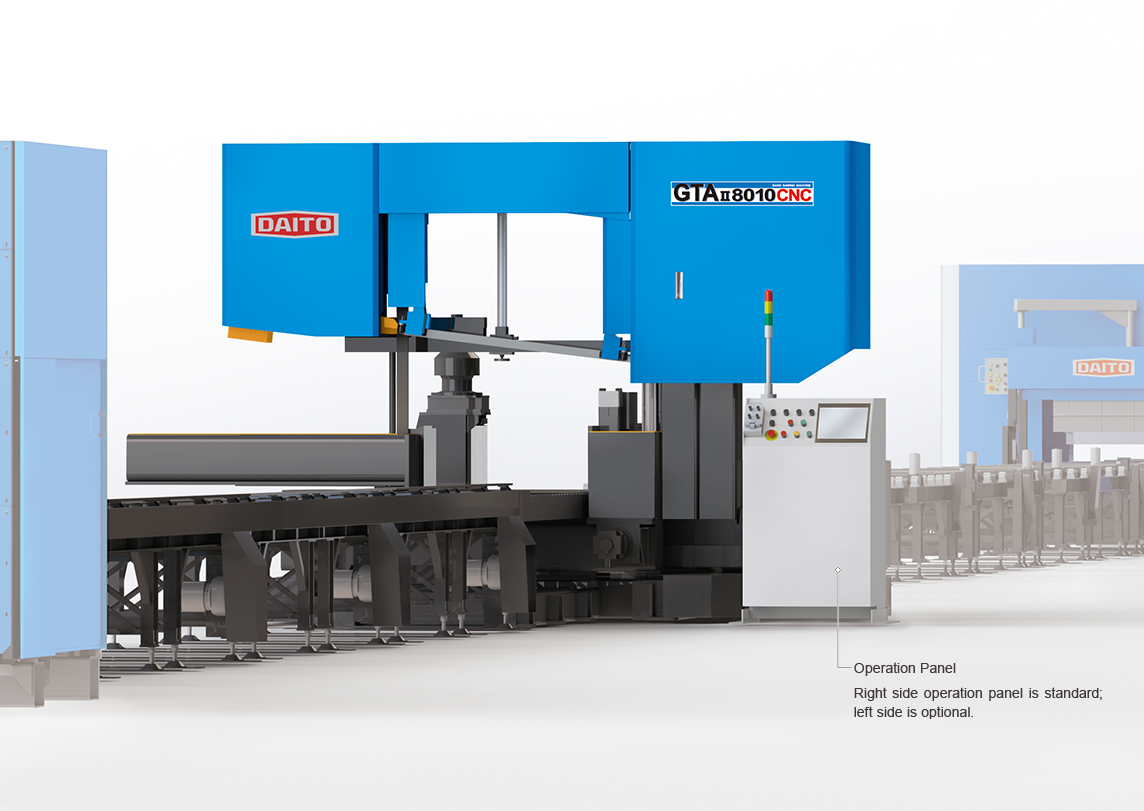

| Product Name | GTAⅡ8010CNC | GTAⅡ1010CNC | GTA6013CNC | |

|---|---|---|---|---|

| Product Photo |  |

|

|

|

| Max. Capacity(W×H) | - | - | - | |

| 31 3/8" | 39 3/8" | 23 5/8" | ||

|

40 1/4" × 29 1/2" |

39 3/8" × 39 3/8" | 51 3/16" × 19 11/16" | ||

| - | - | - | ||

| Overall Dimentions(W×D×H) | 184 3/8" × 236 7/8" × 121 5/8" | 197 5/8" × 218 1/16" × 147 5/8" | 205 11/16" × 241 1/8" × 121 7/16" | |

| Machine Weight | Total 25,620 lbs | 31,000 lbs |

31,000 lbs |

|

GTAⅡ8010CNC is the fully automatic heavy duty production model developed from best-selling GT series; the core machine for DAITO Automatic Structural steel Processing line - DASP.

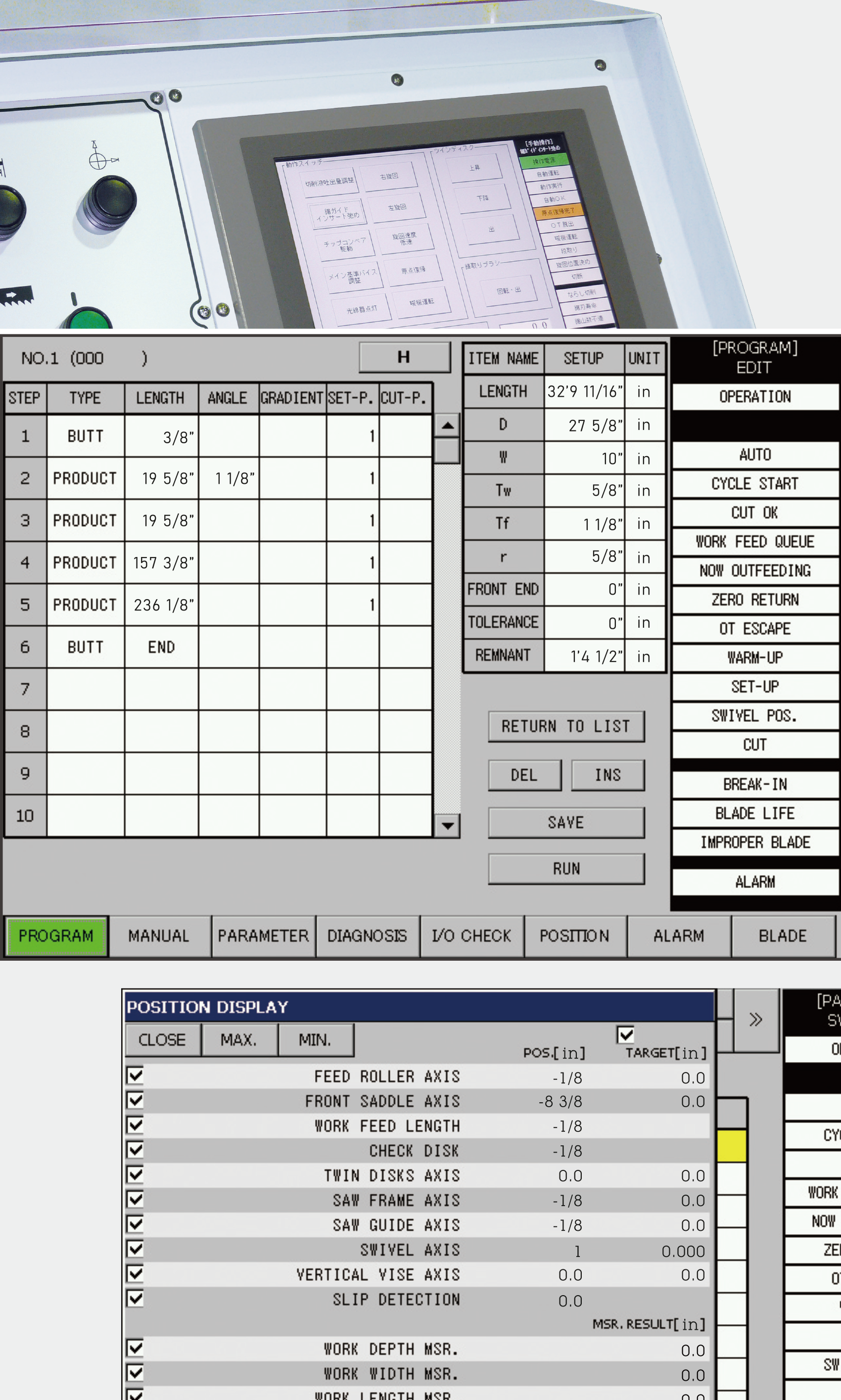

Preset a program and just leave it to the machine.For mitering, both gradient and degree available.

Optimization of the jobs is accomplished by the computerization of blade speed, feed rate, and tool life management.

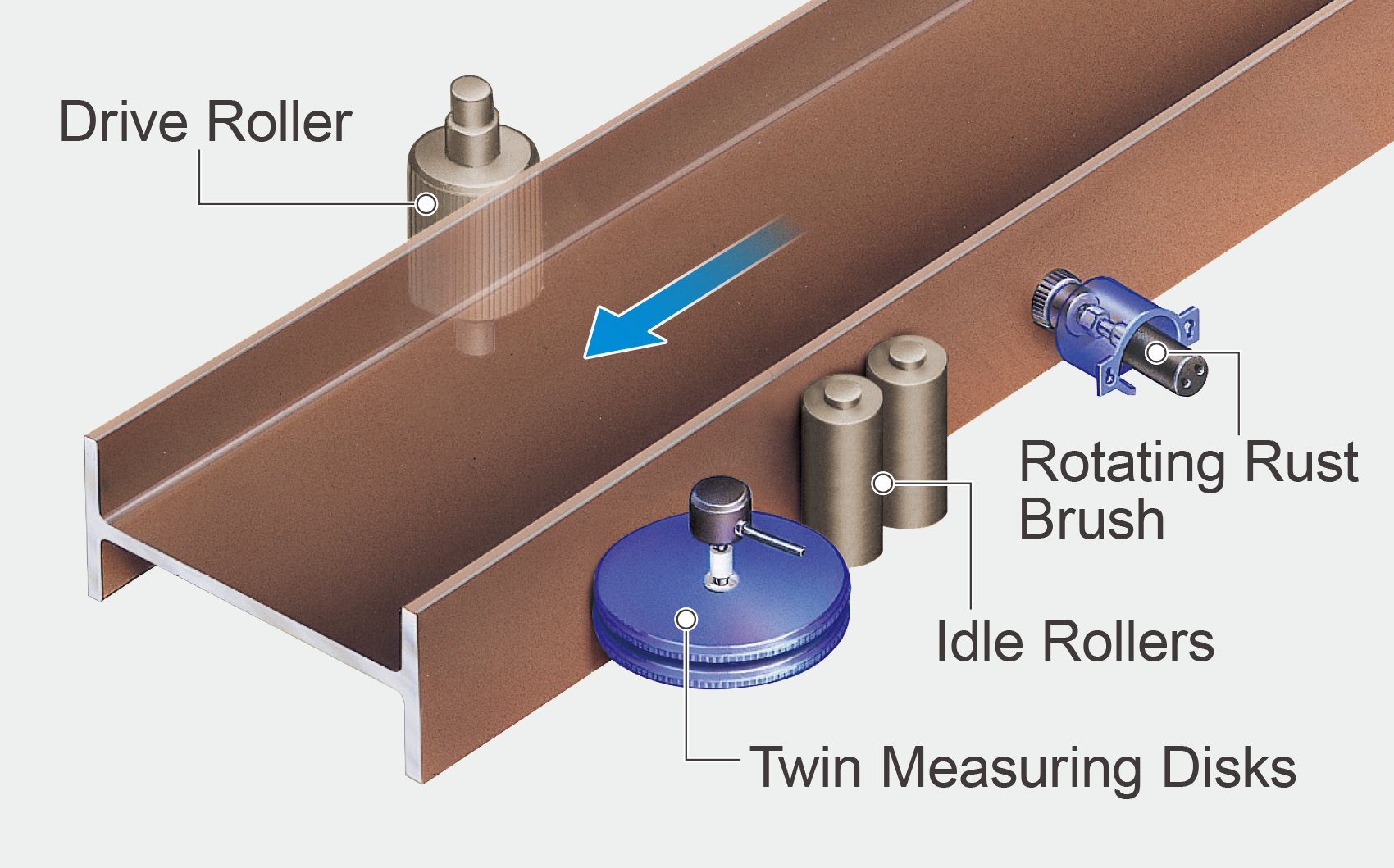

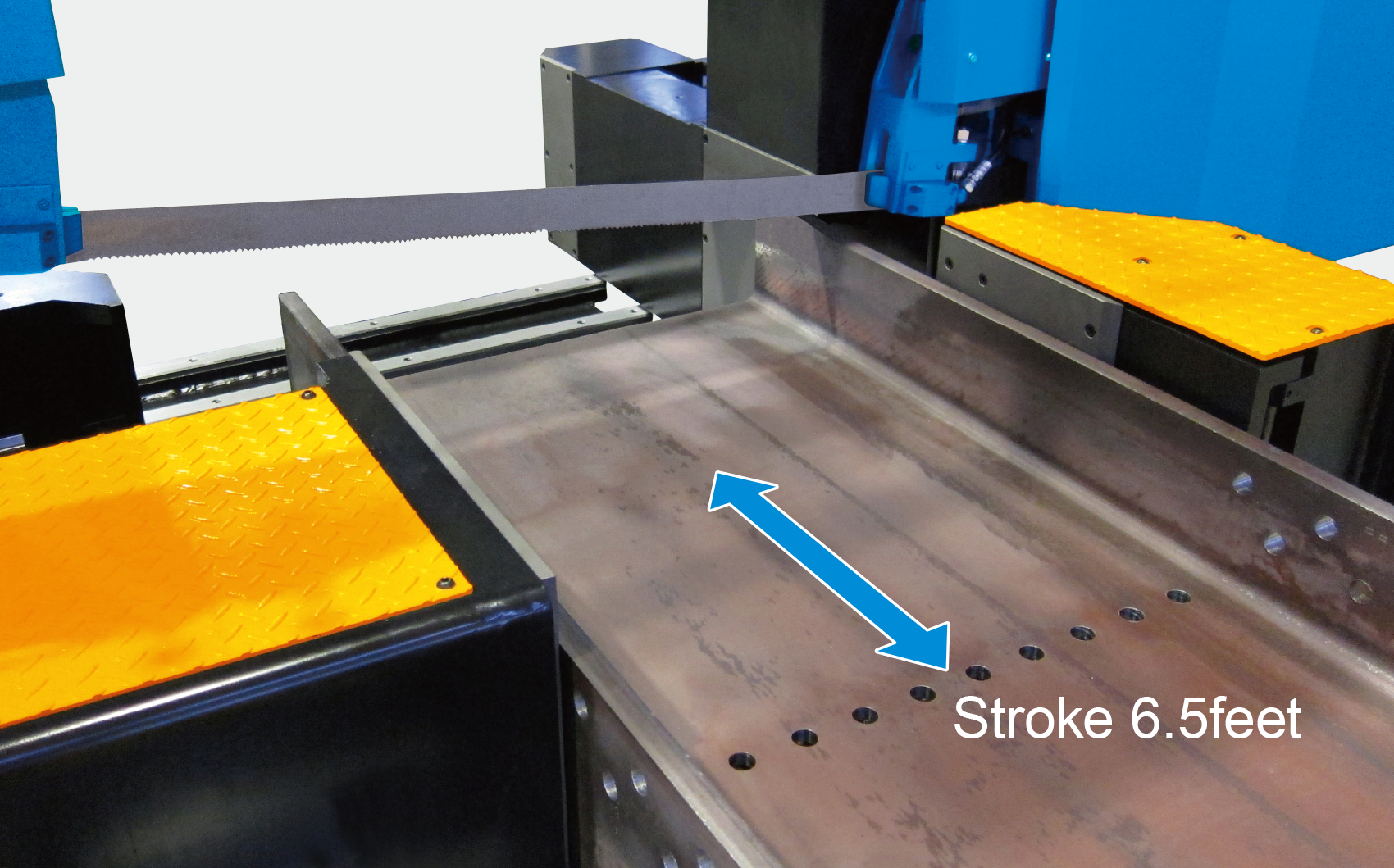

QUICK MEASUREMENT ON ONE FEED

Power pinch rollers quickly position the workpiece. This precise method insures a tolerance of ±0.039” for product length up to 33 feet.

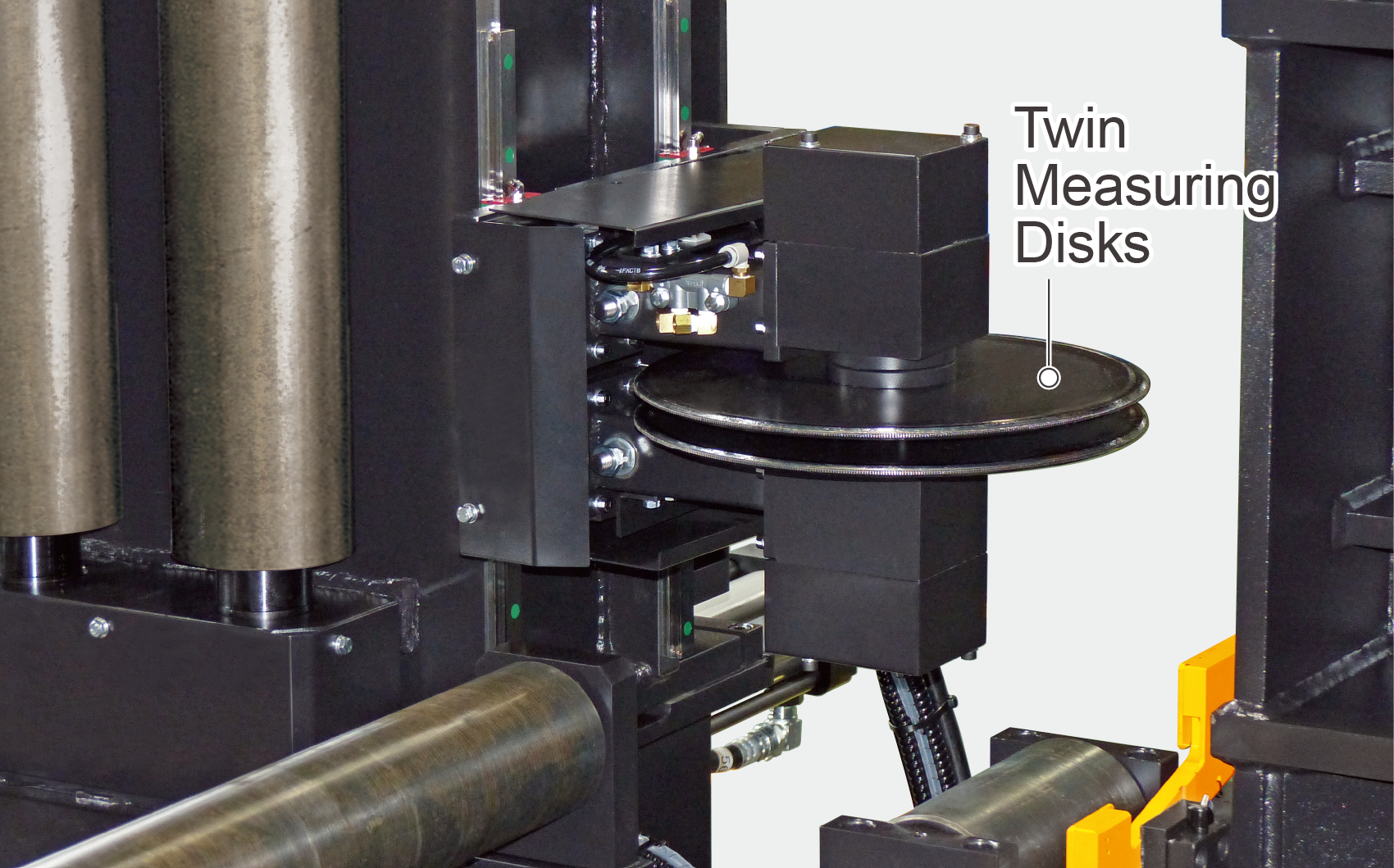

TWIN MEASURING DISKS

The twin disks assure error-free measurement. On measurement difference, the machine alerts to stop malfunctions.

FRONT SHUTTLE VISE

Workpiece remnants and short pieces can be fed off the rollers with the indexable front shuttle vise.

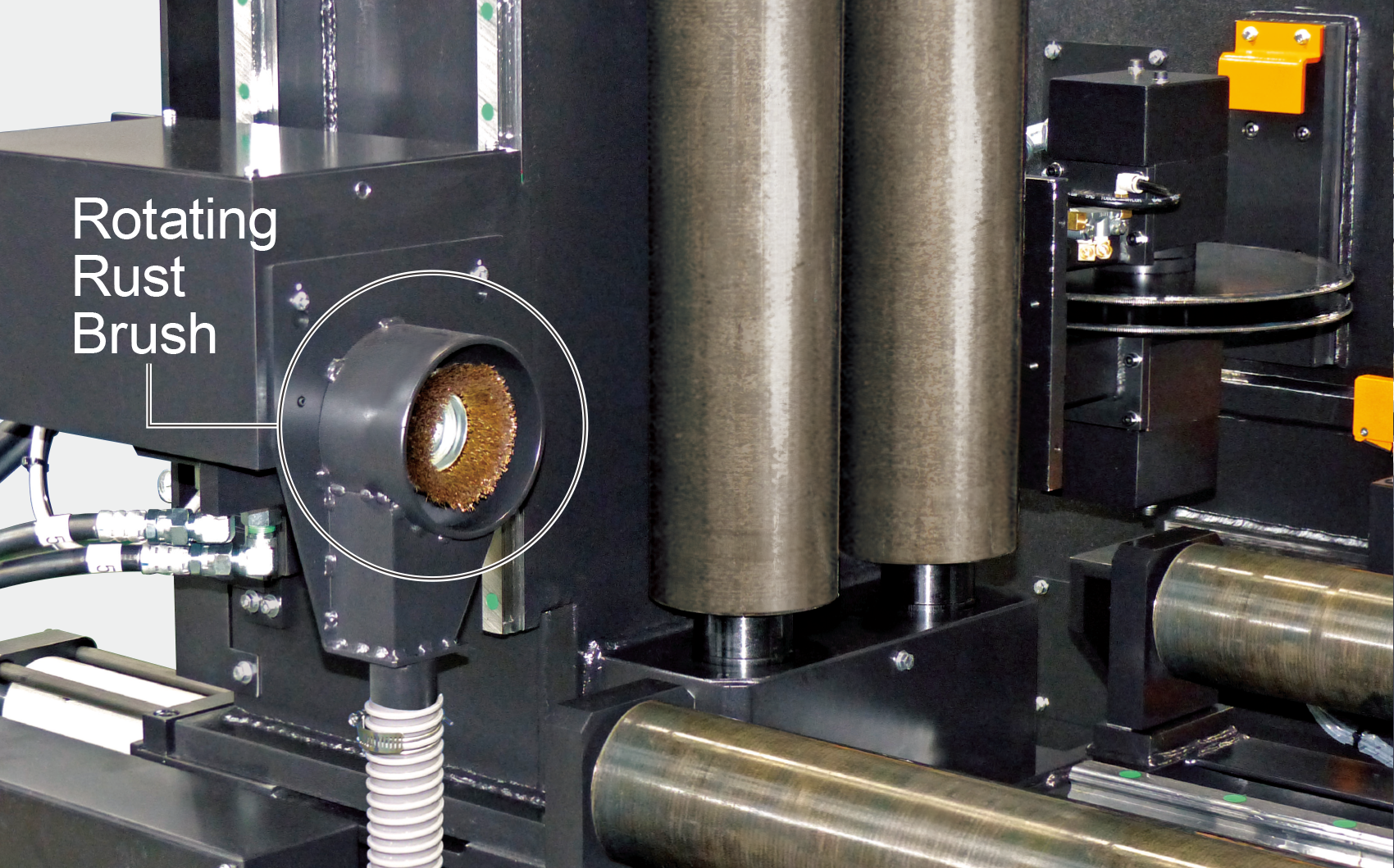

ROTATING RUST BRUSH

The cup brush behind the measuring disks wipes out rust and dirt on workpiece for accurate measurement.

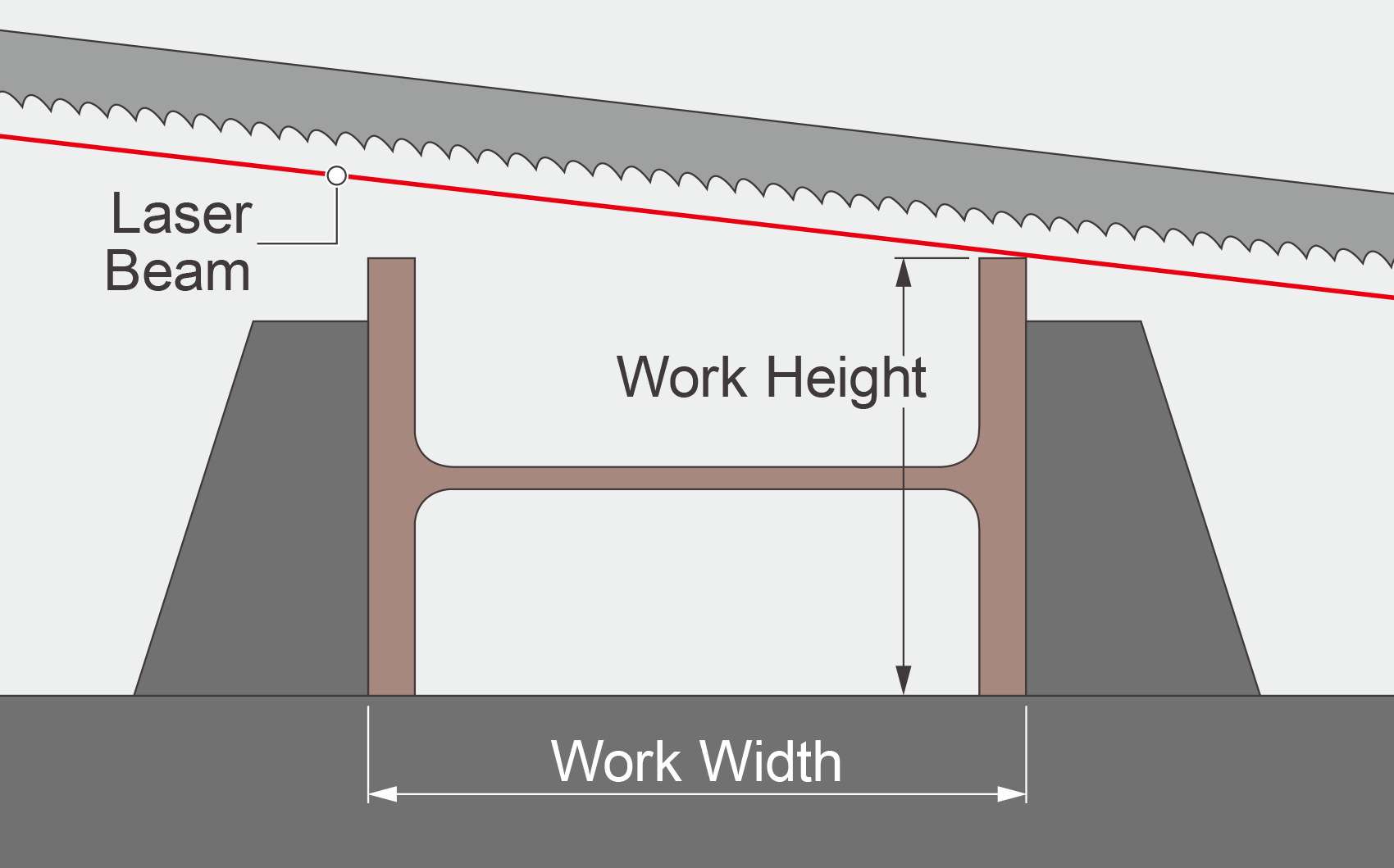

WORKPIECE VERIFICATION

Work width is measured when clamped. Work height is measured when the laser beam under the blade contacts the workpiece enabling easy operation.

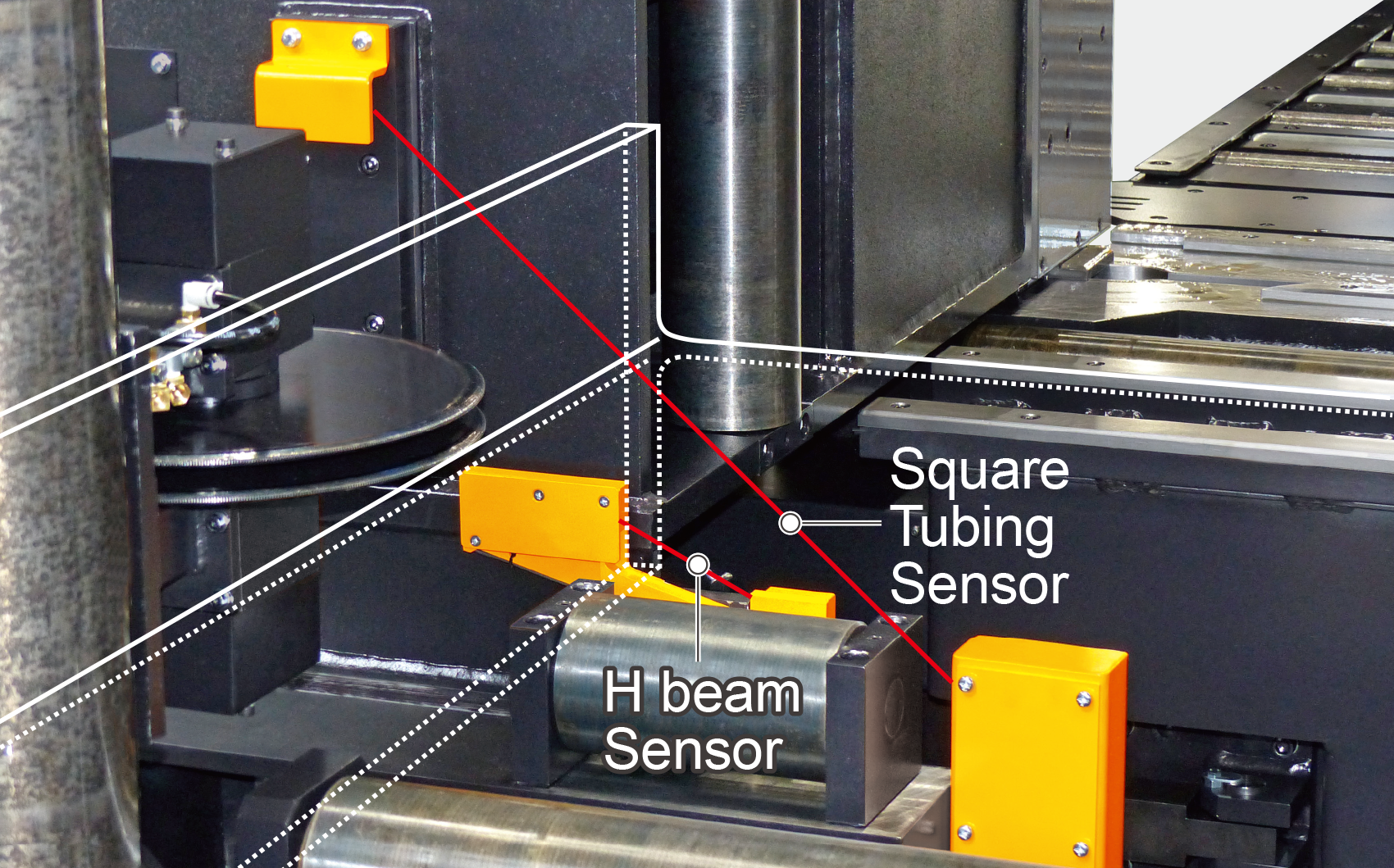

WORKPIECE FRONT END DETECTION

The front end of workpiece (illustrated H beam) is detected by sensors for positioning; no need for manual measurement.

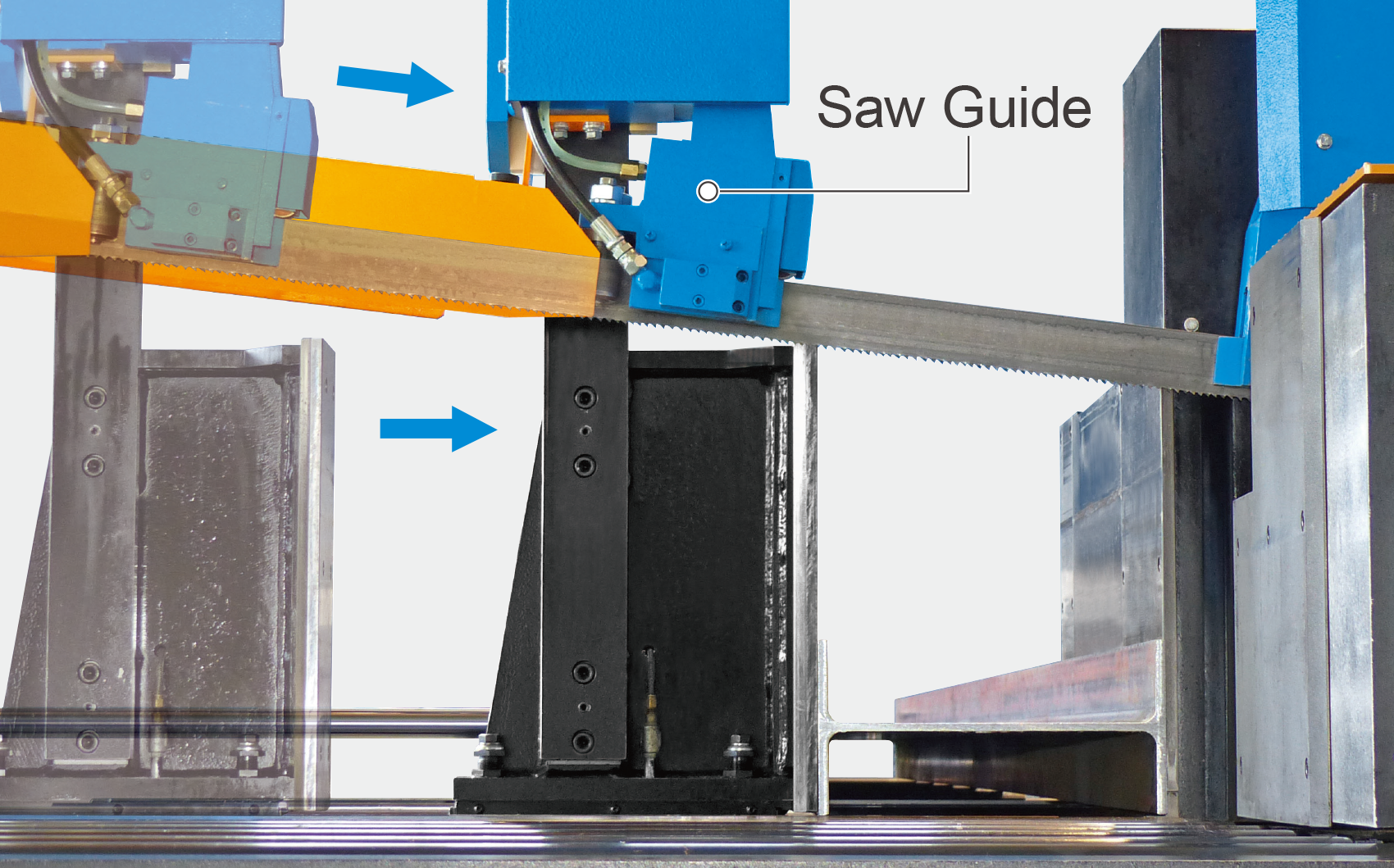

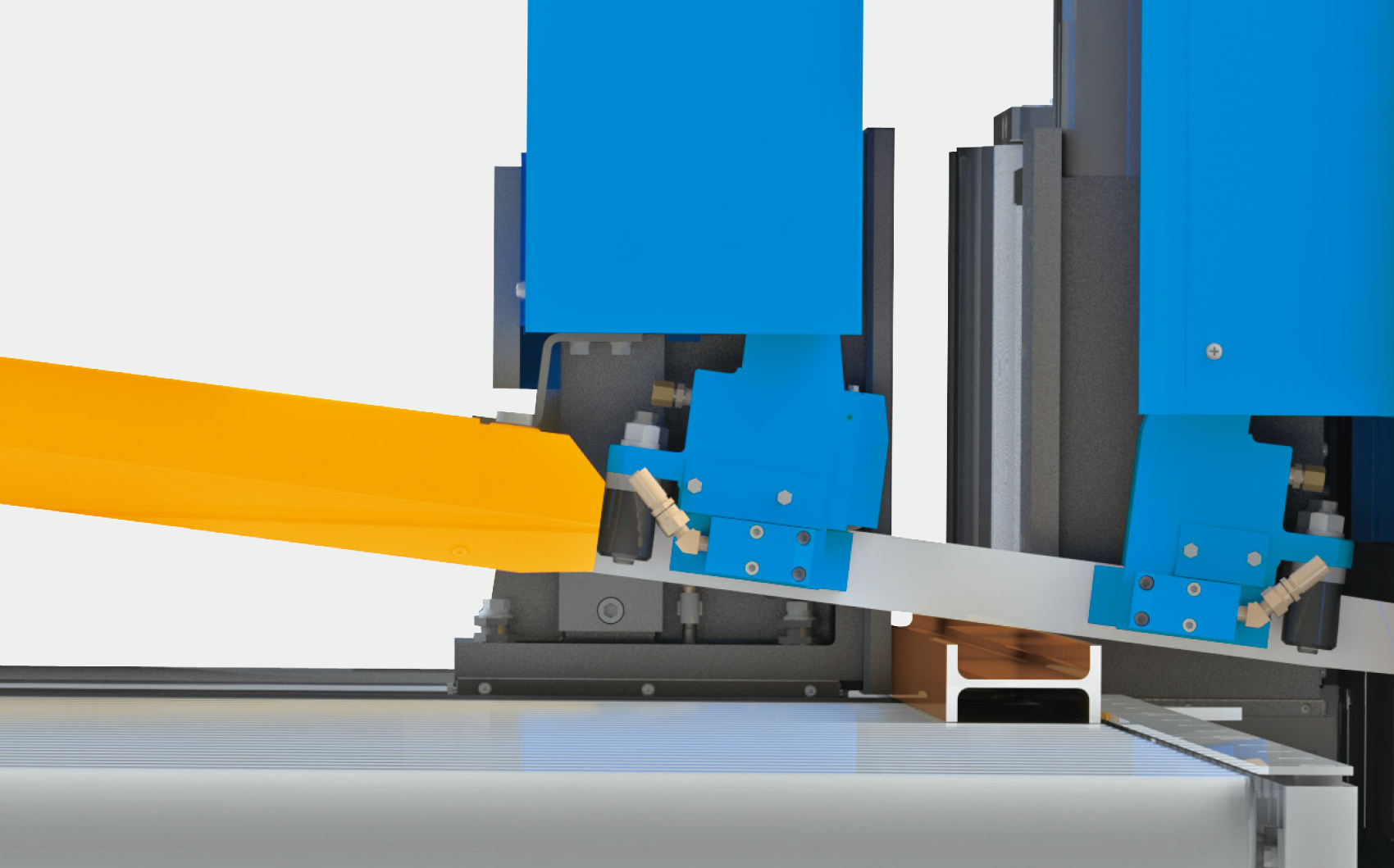

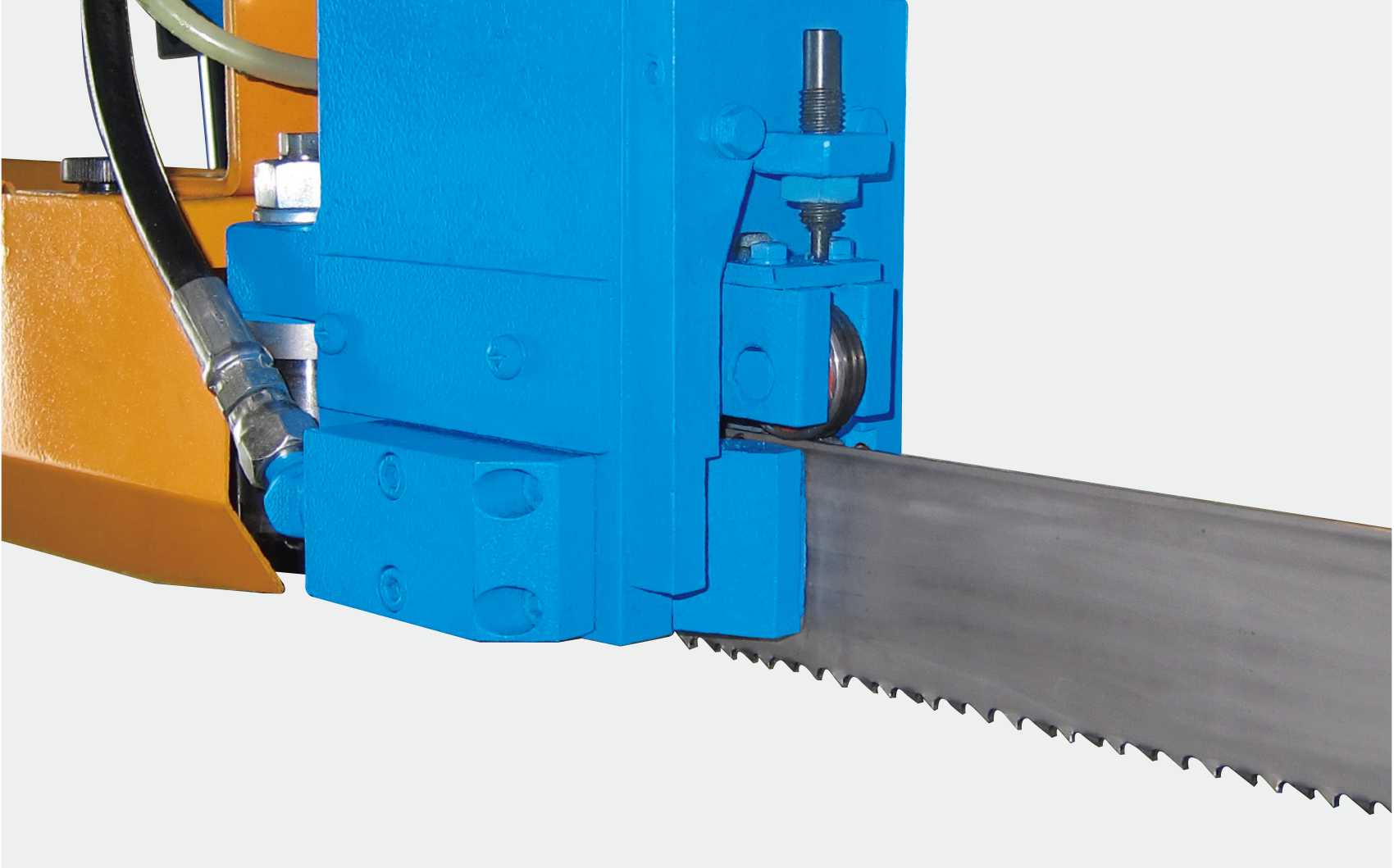

SAW GUIDE LINKED WITH VISE

Being linked with the vise, the left side saw guide is always close to the workpiece and the insert tips are hydraulically loaded for the best blade conditions.

WIDE CUTTING CAPACITY

From 4” to 40 1/4” wide workpiece can be clamped and cut.

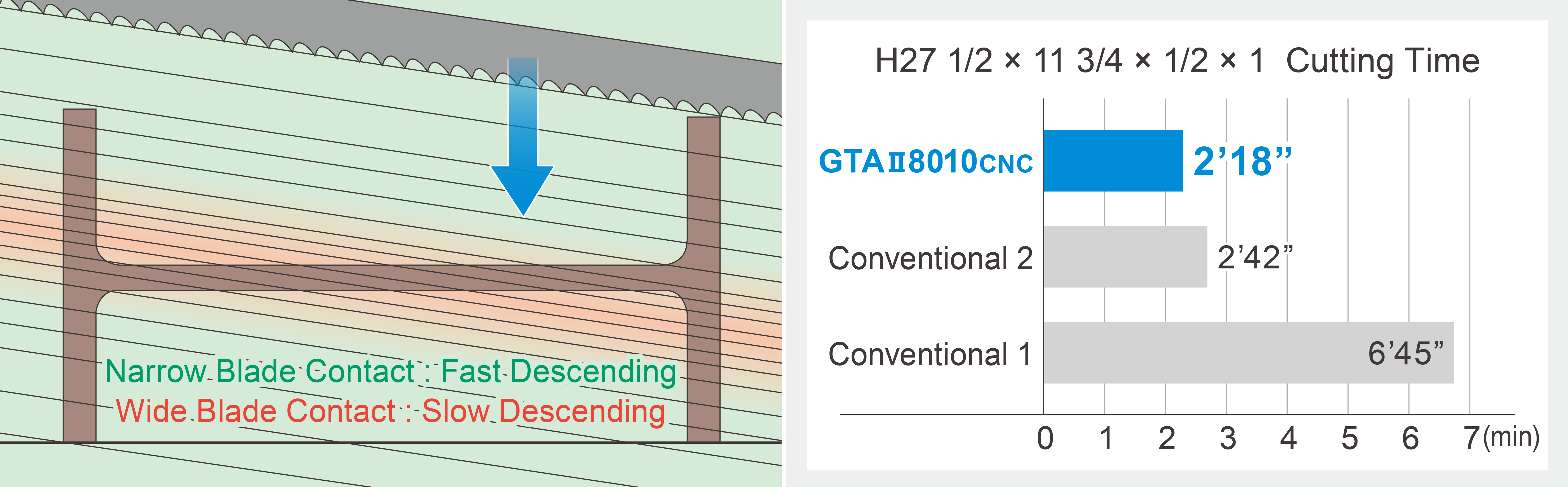

The CNC control with profile memory helps improve blade life and overall speed.

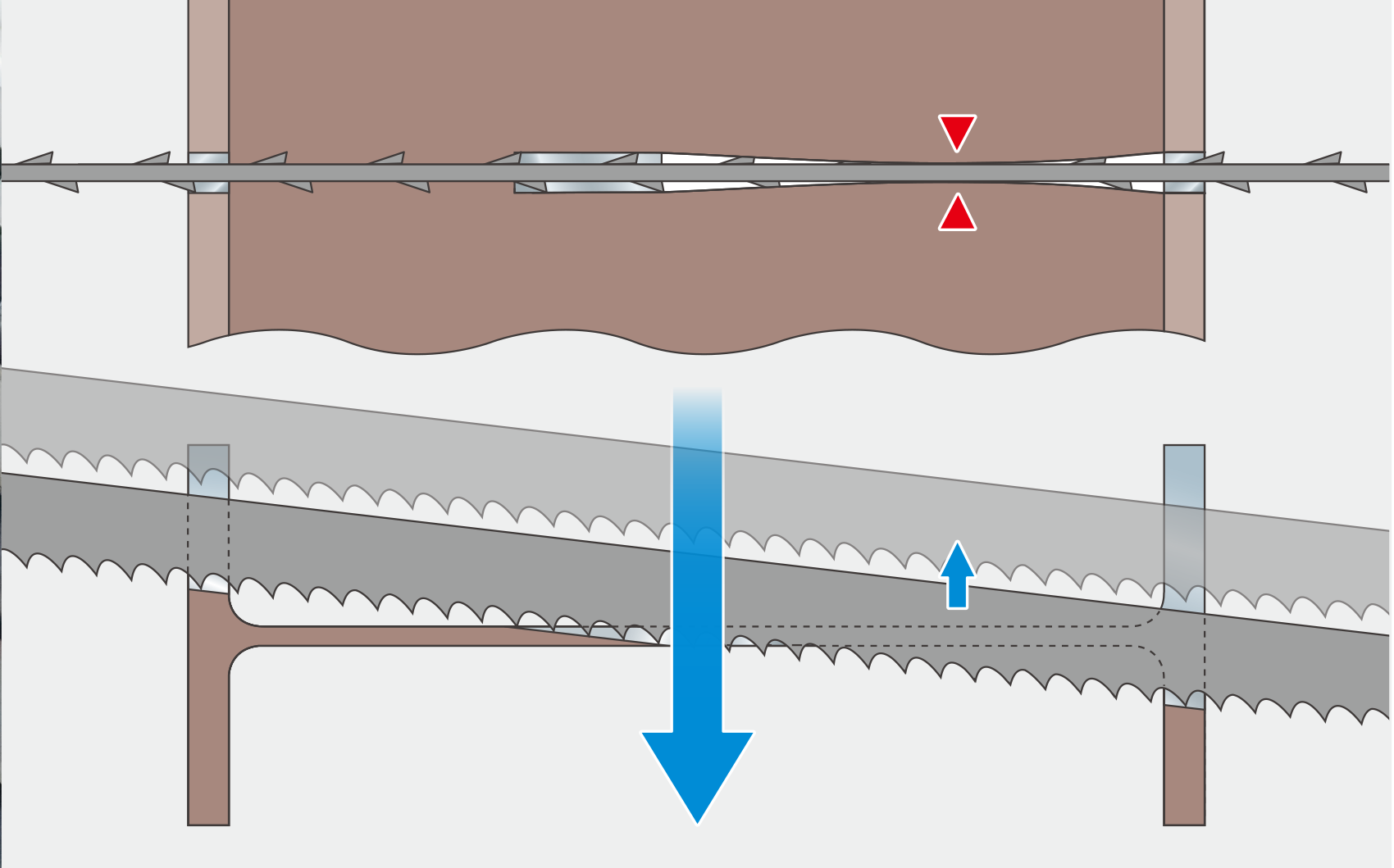

PINCHING ESCAPE

Saw blade pinching due to beam inner stress is eliminated by DAITO’s unique proactive step-feed method.

LOWER CUTTING NOISE

The vibration damper roller reduces cutting noise; increases blade life.

SAW FRAME LINEAR GUIDES

The saw frame goes up and down on linear guides reducing friction for more smooth and accurate blade feeding.

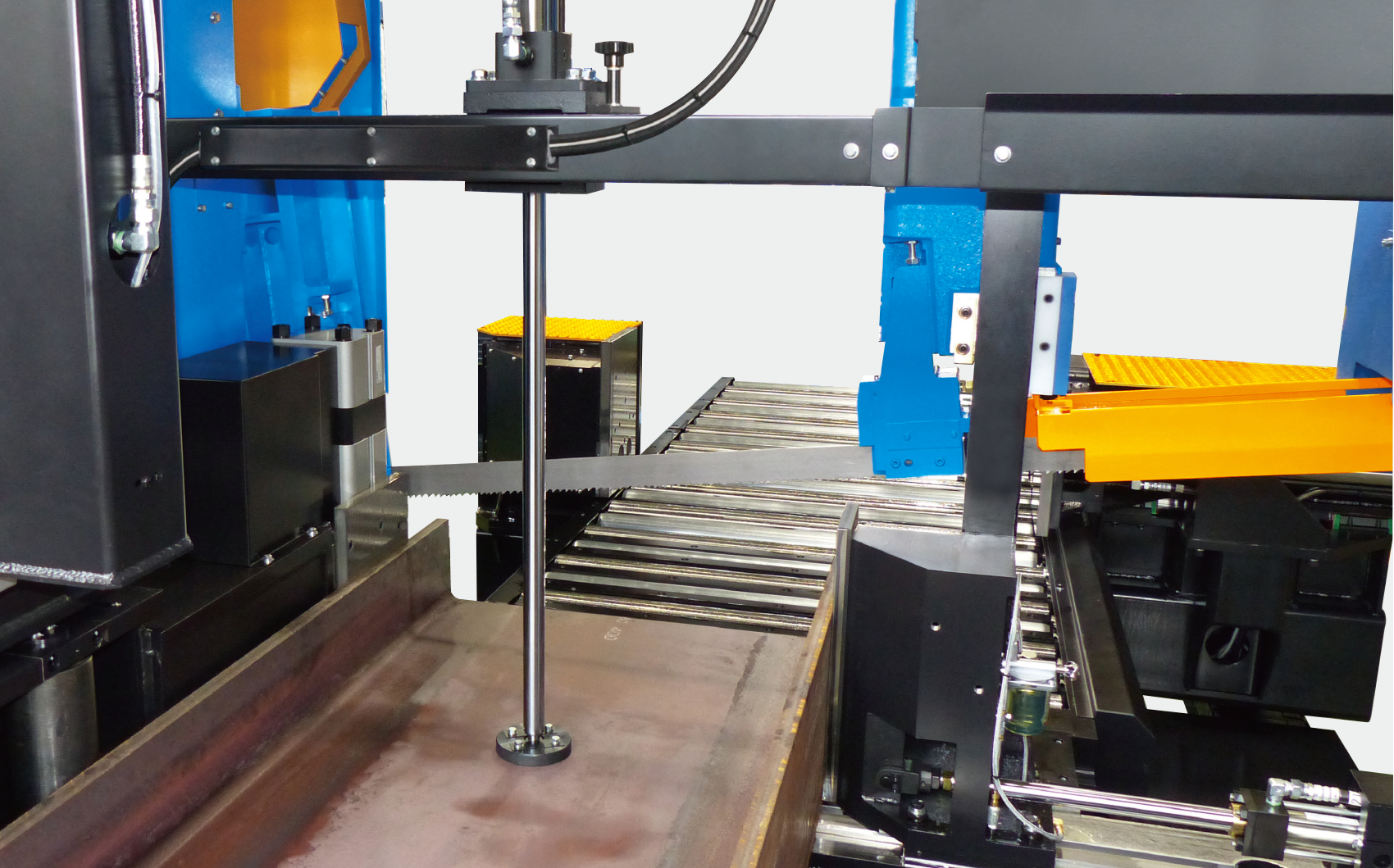

VERTICAL VISE

The vertical vise is positioned automatically at the center of the workpiece to dampen the vibrations that can cause blade damage and failures.

REMOTE CONTROL BOX

The commonly used switches such as frame/vise are also on the remote control box.

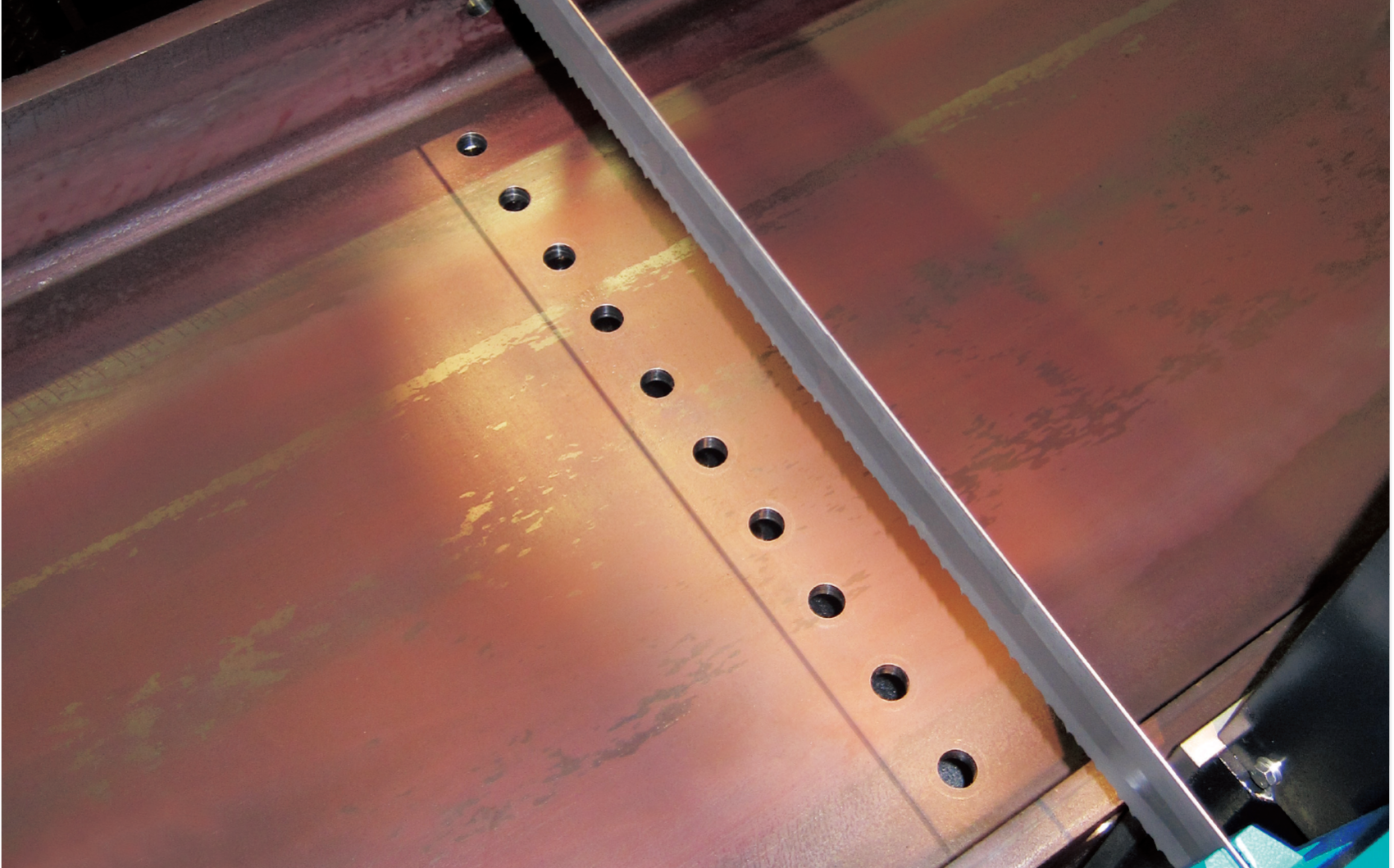

CLEAR SHADOW LINE

The cutting position is projected by the strong LED; the shadow is even clear in a bright working environment to make work positioning easy.

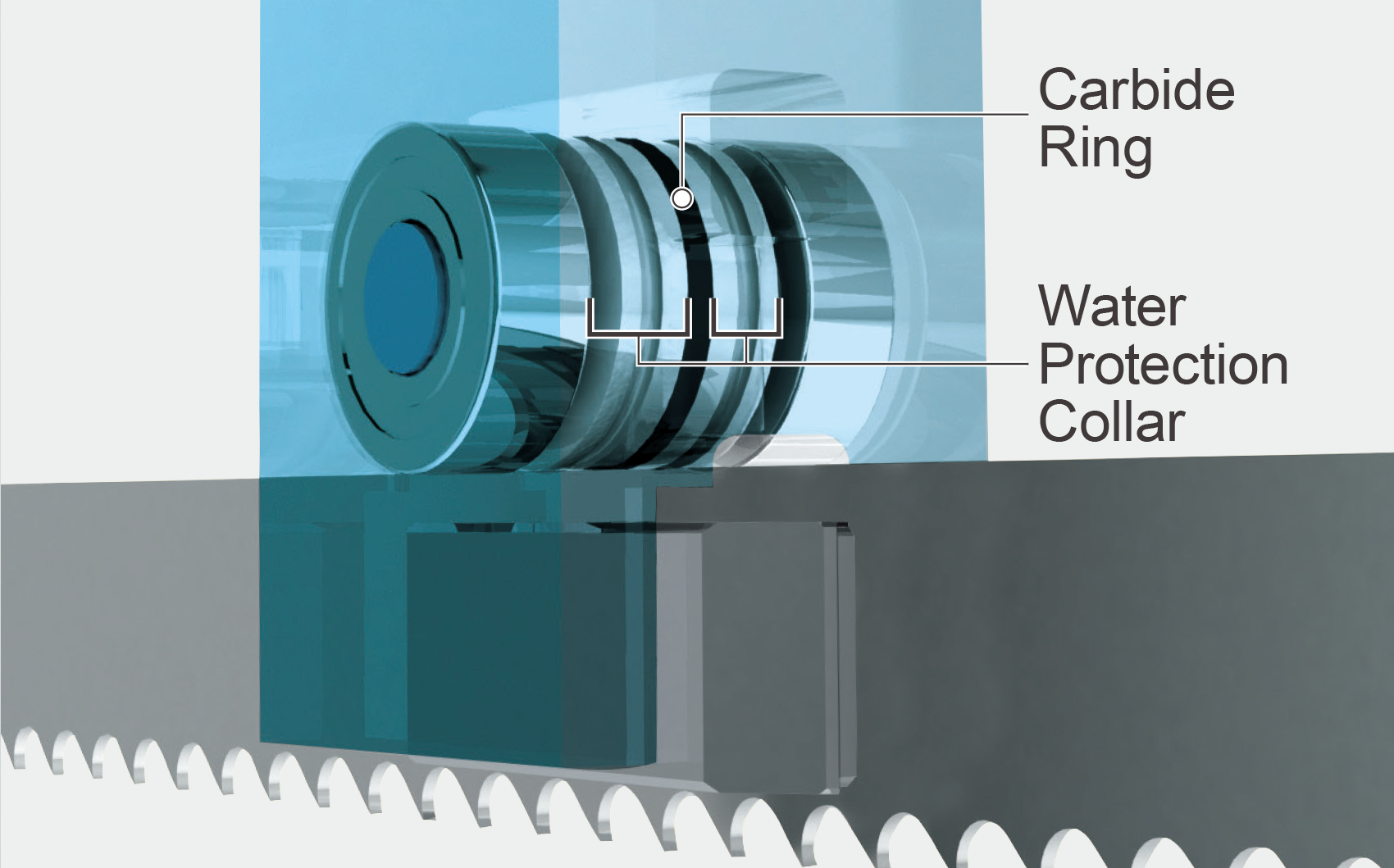

CARBIDE BACK-UP ROLLER

The carbide back-up roller placed between bearings which are isolated from cutting fluid assures long life of the equipment.

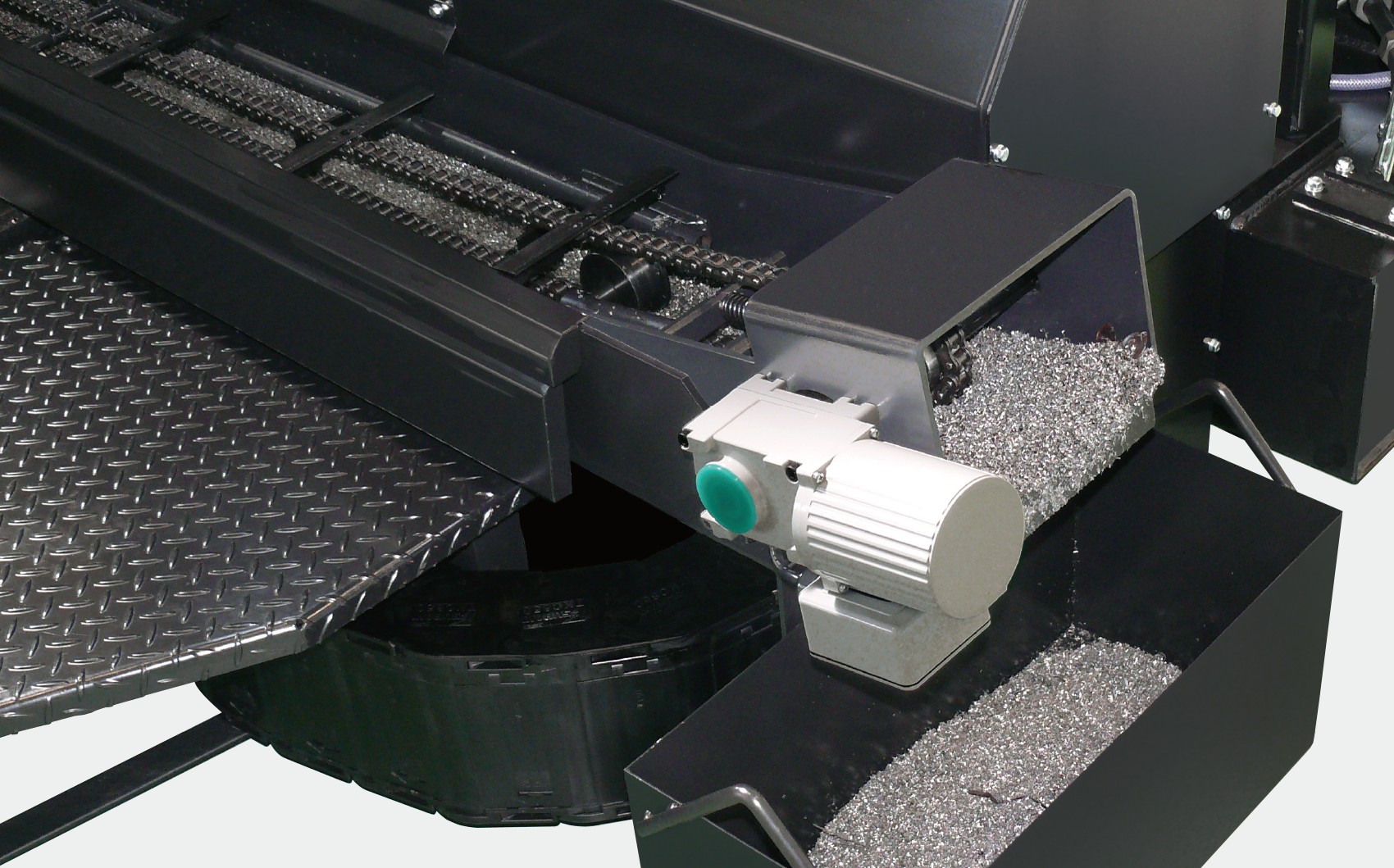

CHIP CONVEYOR

The chain-driven rakes remove saw chips smoothly separating coolant.

Roller tables are to be placed on the infeed and outfeed side of the machine. The tables come with 3,5,7,10 or 20 rollers per table depending on jobs.

The powered roller is linked with a roller table; lifts up workpiece by hydraulics and feed it to the machine driven by the motor.

The workpiece is pushed against the vertical rollers for precise alignment.

The traverse carts lift up and traverse workpiece to the conveyor lines.

The rollers of the fall-free table are placed close together with 5” pitch and turned on/off freely to carry even small cut pieces.

The laser beam helps to position workpiece when a markings are made on the left flange.

From each machine to total automation, contact us freely.

9:00~17:00: phone available

847-437-6788(Head Sales Office)