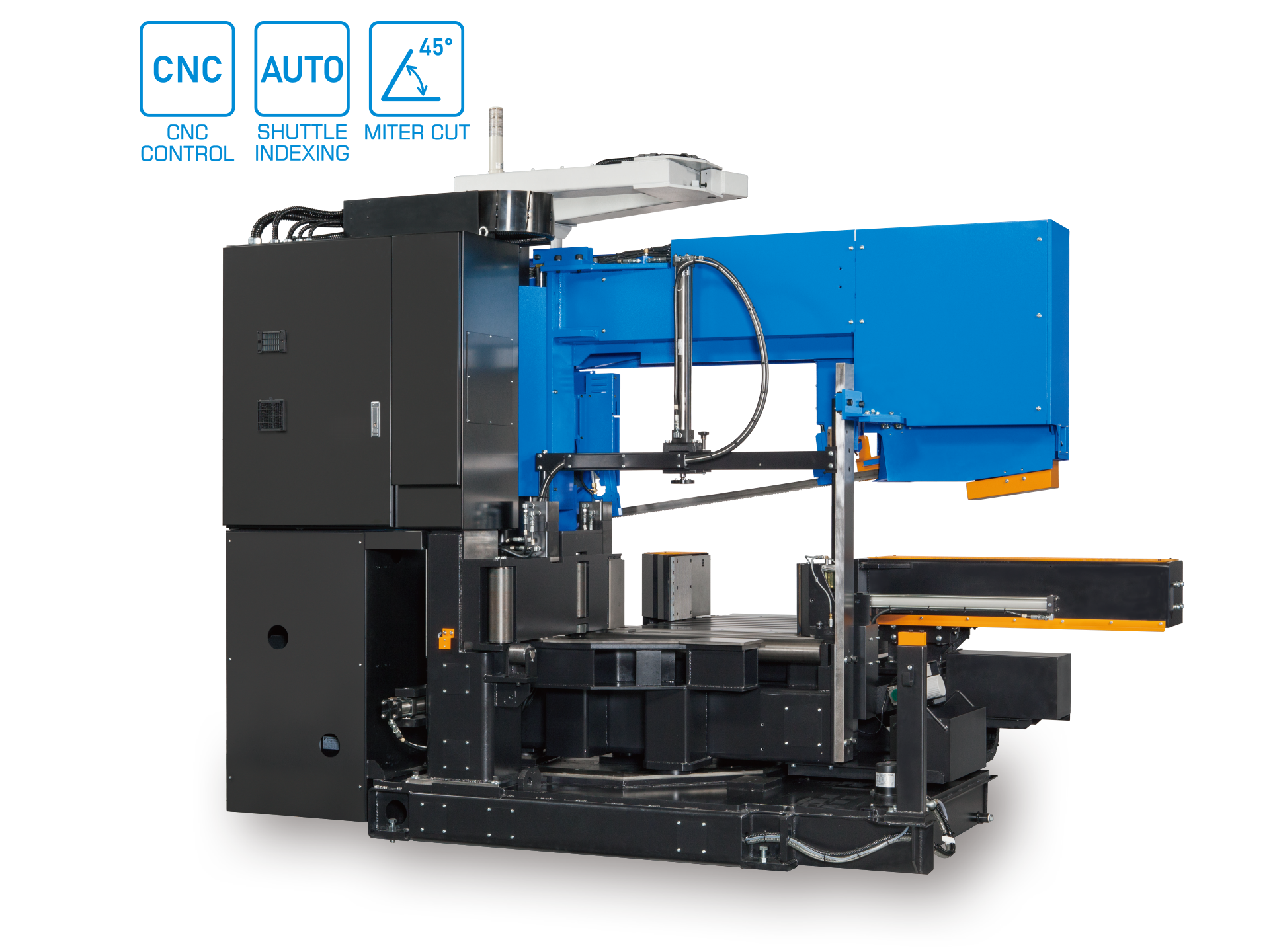

BAND SAWING MACHINE

The automatic CNC band saw with a miter cut feature;

available to be incorporated to a fully automated line system.

| product |

GTEⅡ5580CNC |

|

|---|---|---|

| product photo |  |

|

| Max. Capacity(W×H) | 21 5/8" | |

| 21 5/8" | ||

| 31 3/8" × 15 5/8" | ||

| - | ||

| Overall Dimentions (W×D×H) | 143"×104 1/8"×121 3/8" | |

| Machine Weight | 14,220 lbs | |

Economical automatic machine with no feeder on the infeed side of the machine; the indexing is made by a shuttle type front vise.

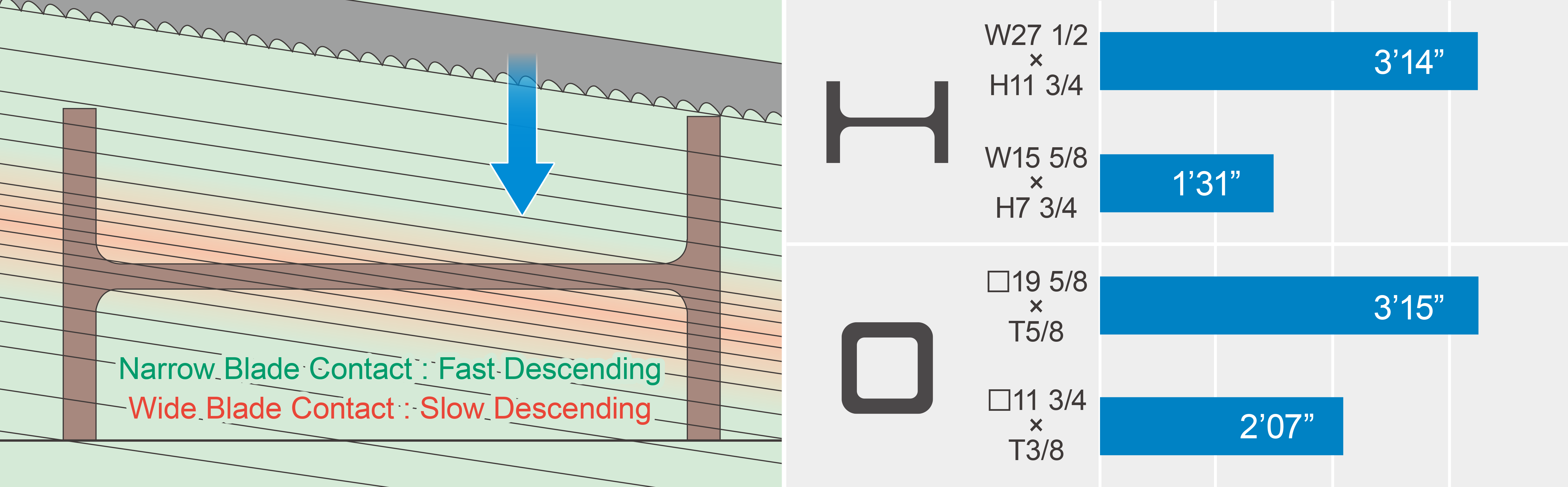

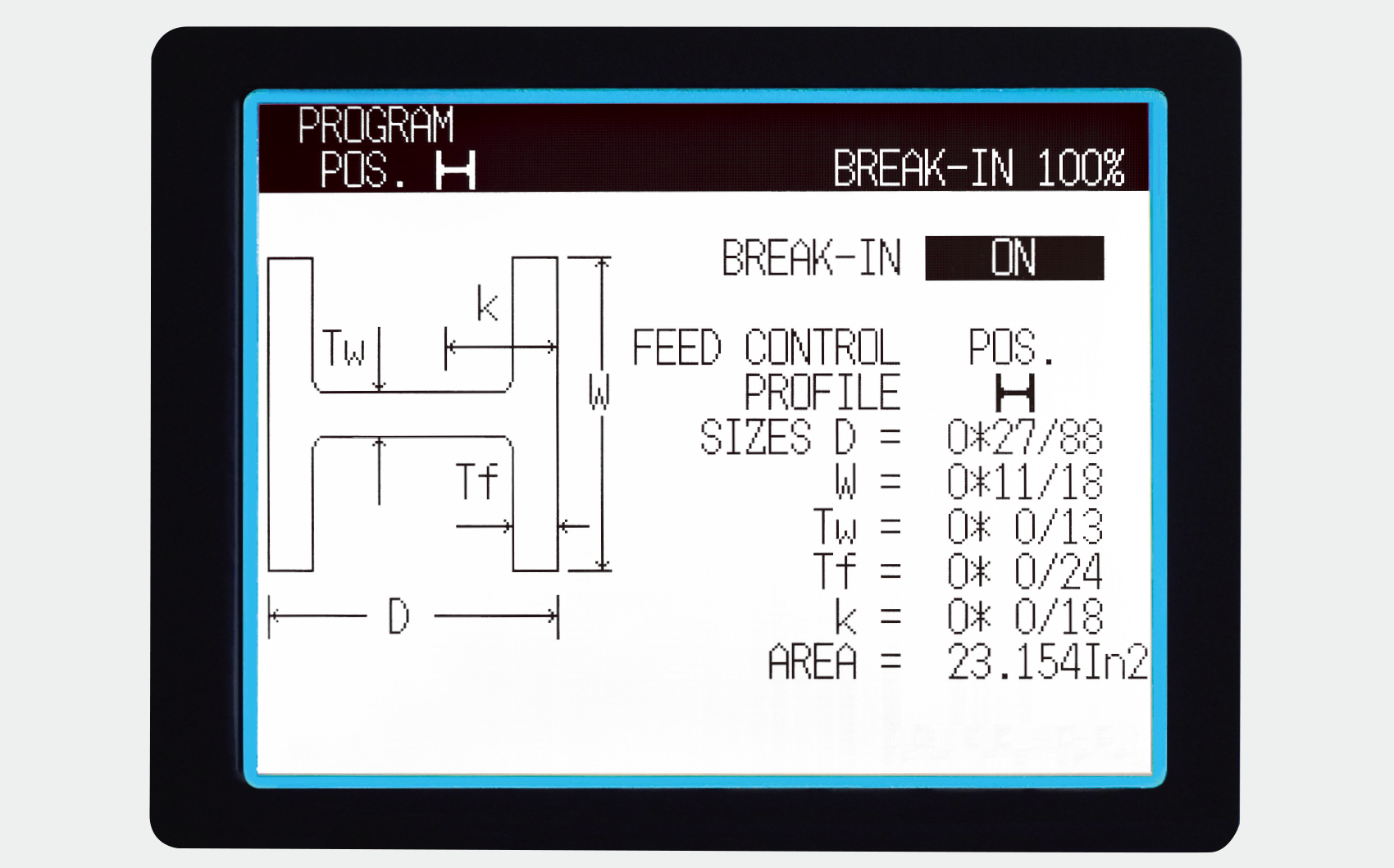

The CNC control with profile memory helps improve blade life and overall speed.

The CNC optimization program enabled longer blade life with less cutting vibration.

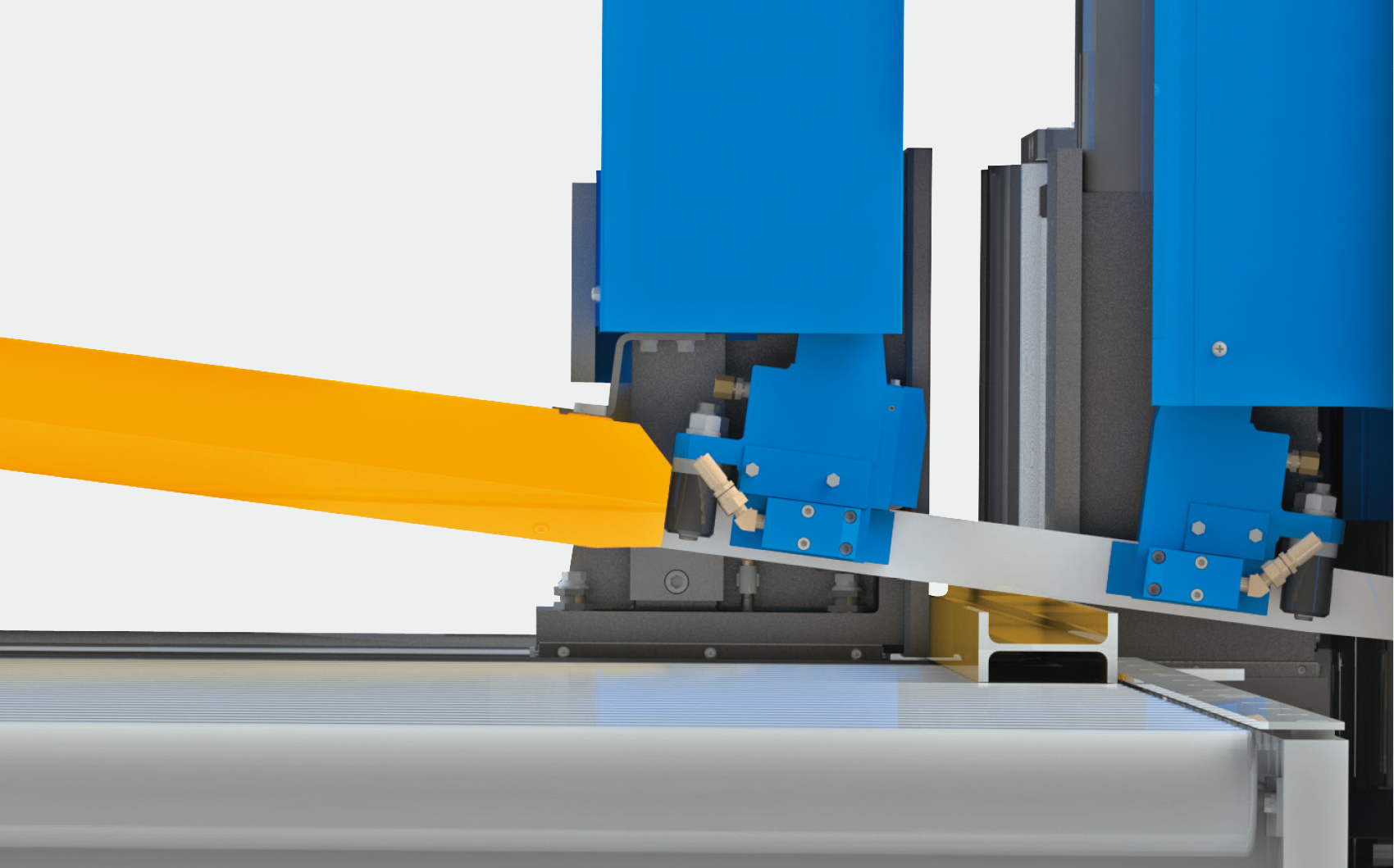

EASY MITER CUT

Miter cutting up to 45 degrees is automatically accomplished depending on the entered data. Maximum of 24 angles stored in the computer.

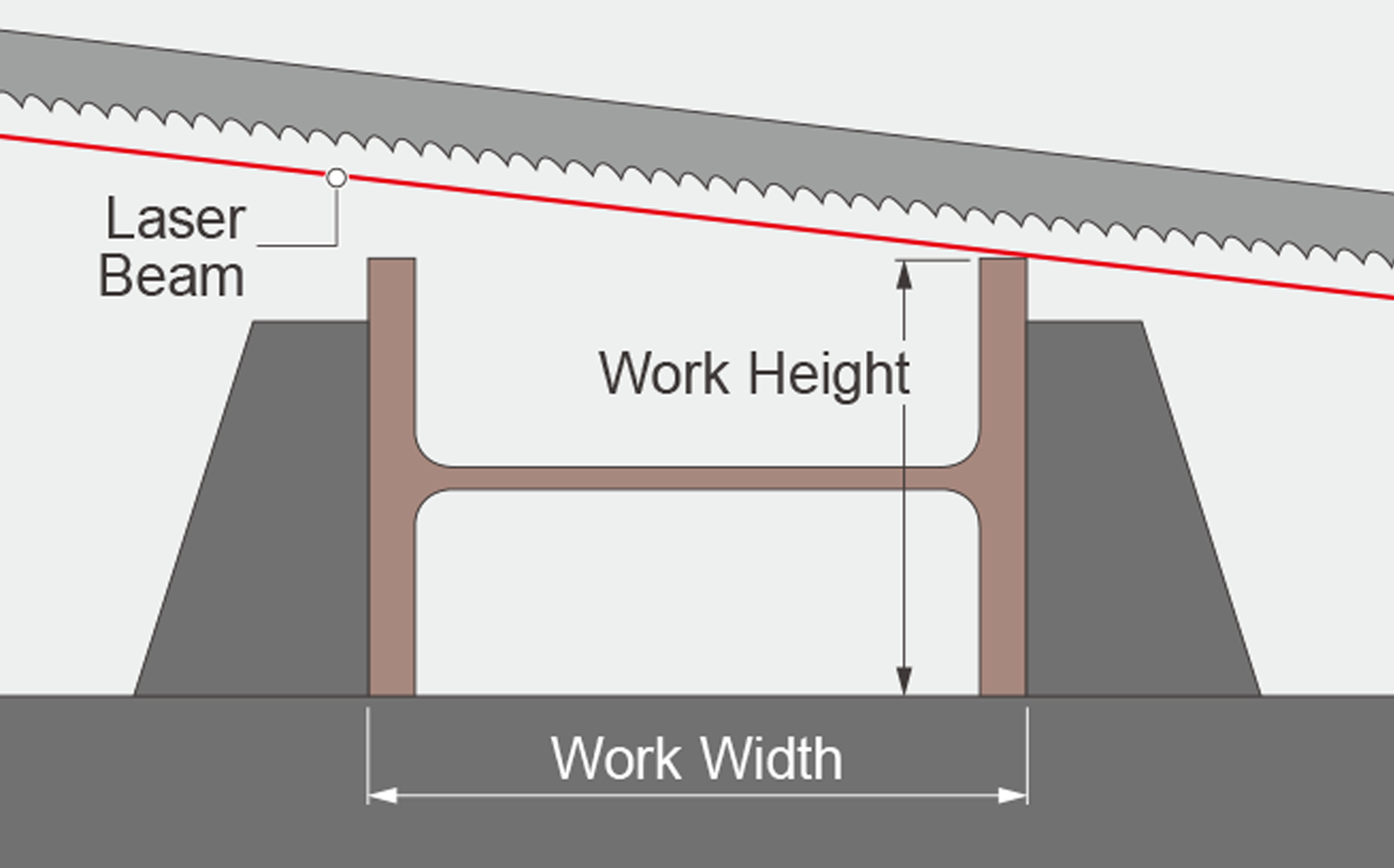

WORKPIECE VERIFICATION

Work width is measured when clamped. Work height is measured when the laser beam under the blade contacts the workpiece enabling easy operation.

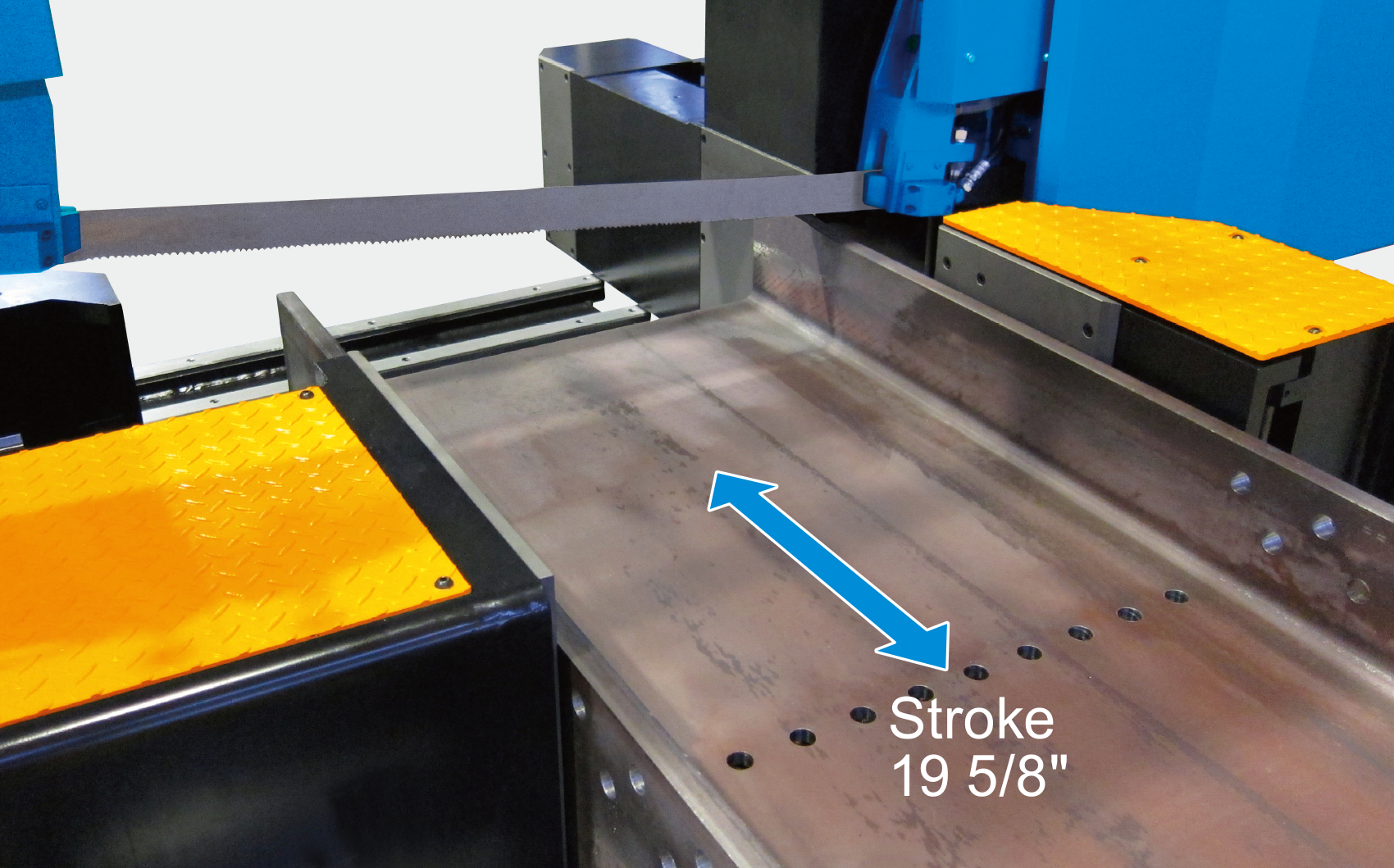

FRONT SHUTTLE VISE

Workpiece remnants and short pieces can be fed off the rollers with the indexable front shuttle vise.

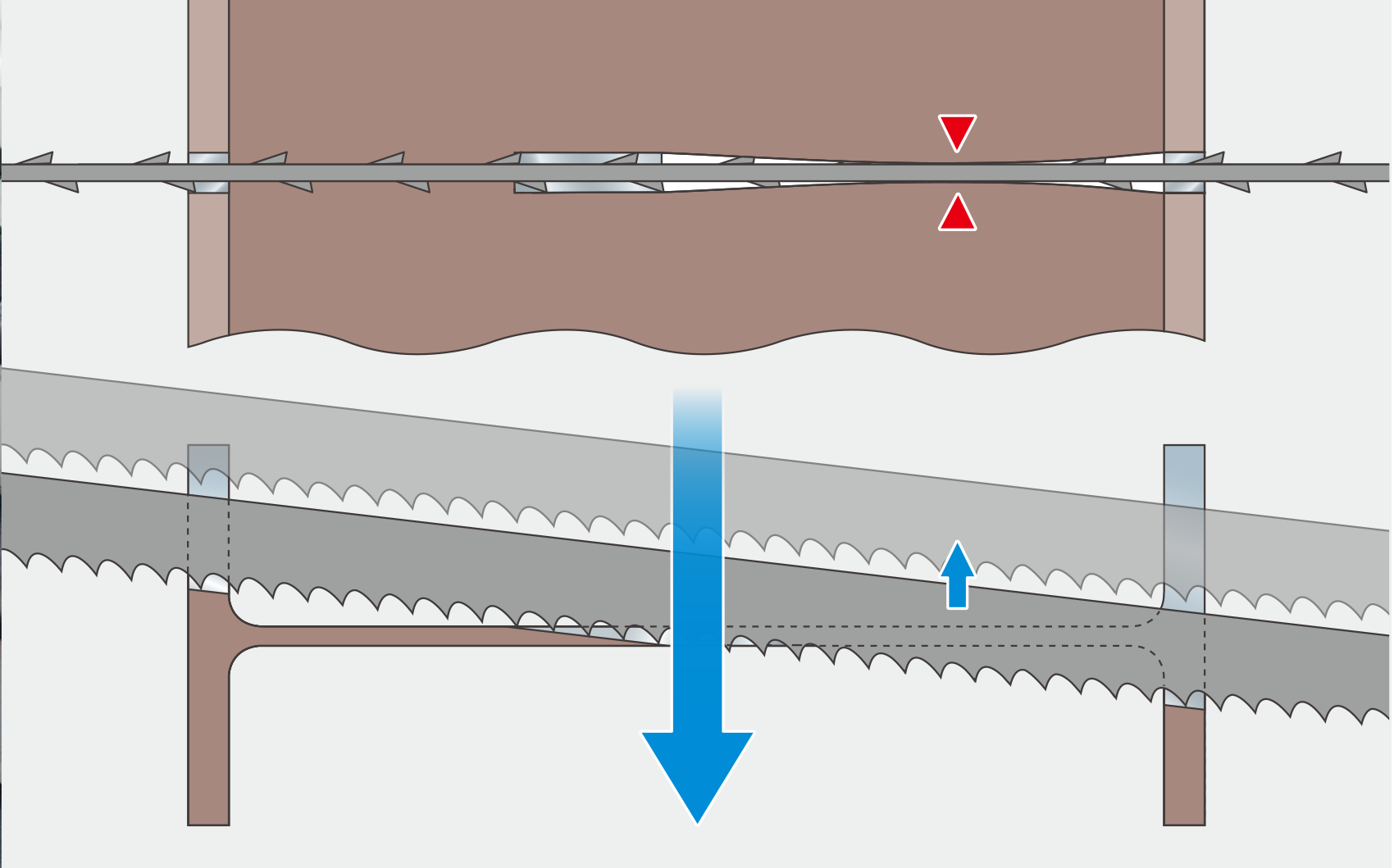

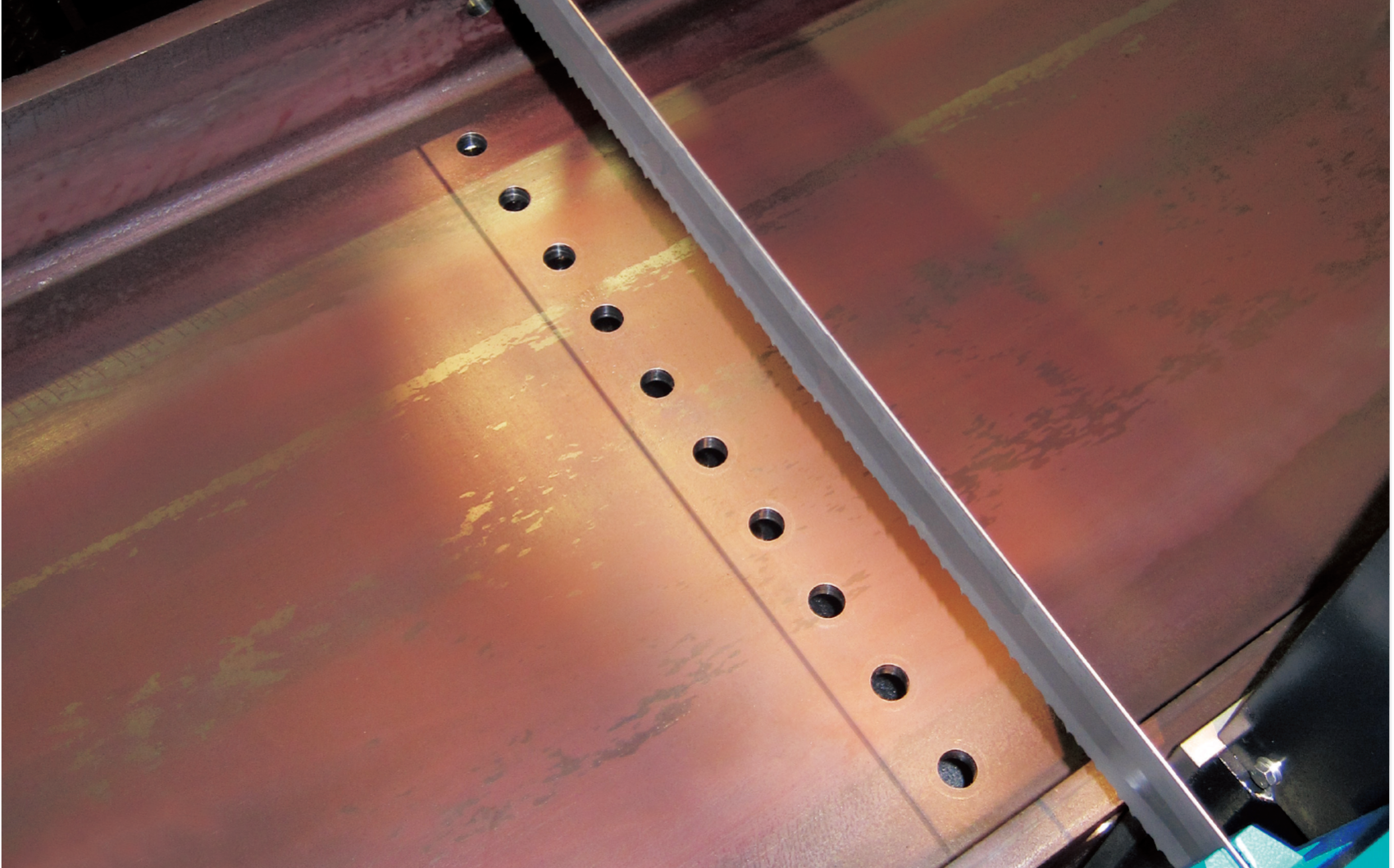

PINCHING ESCAPE

Saw blade pinching due to beam inner stress is eliminated by DAITO’s unique proactive step-feed method.

LOWER CUTTING NOISE

The vibration damper roller reduces cutting noise; increases blade life.

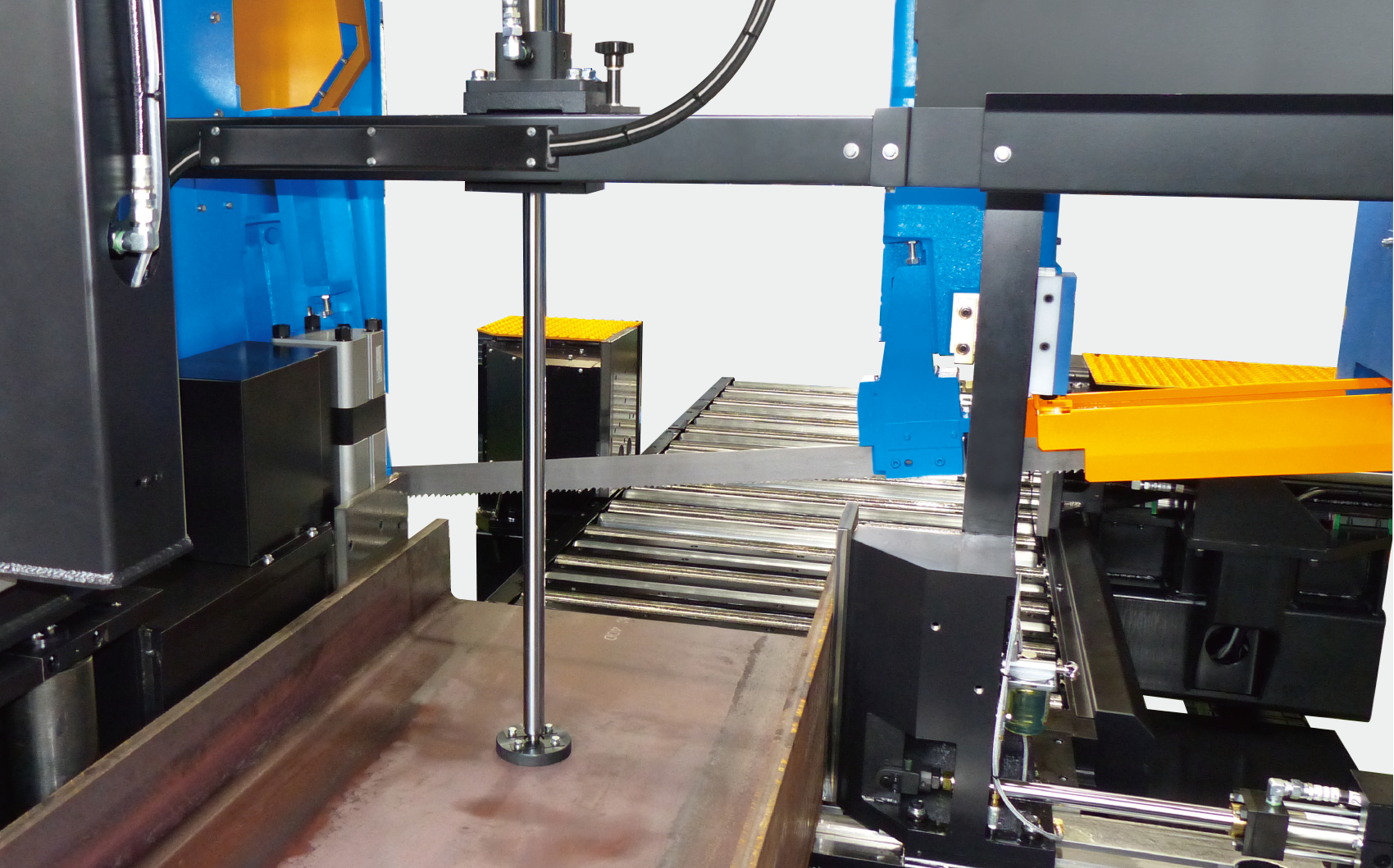

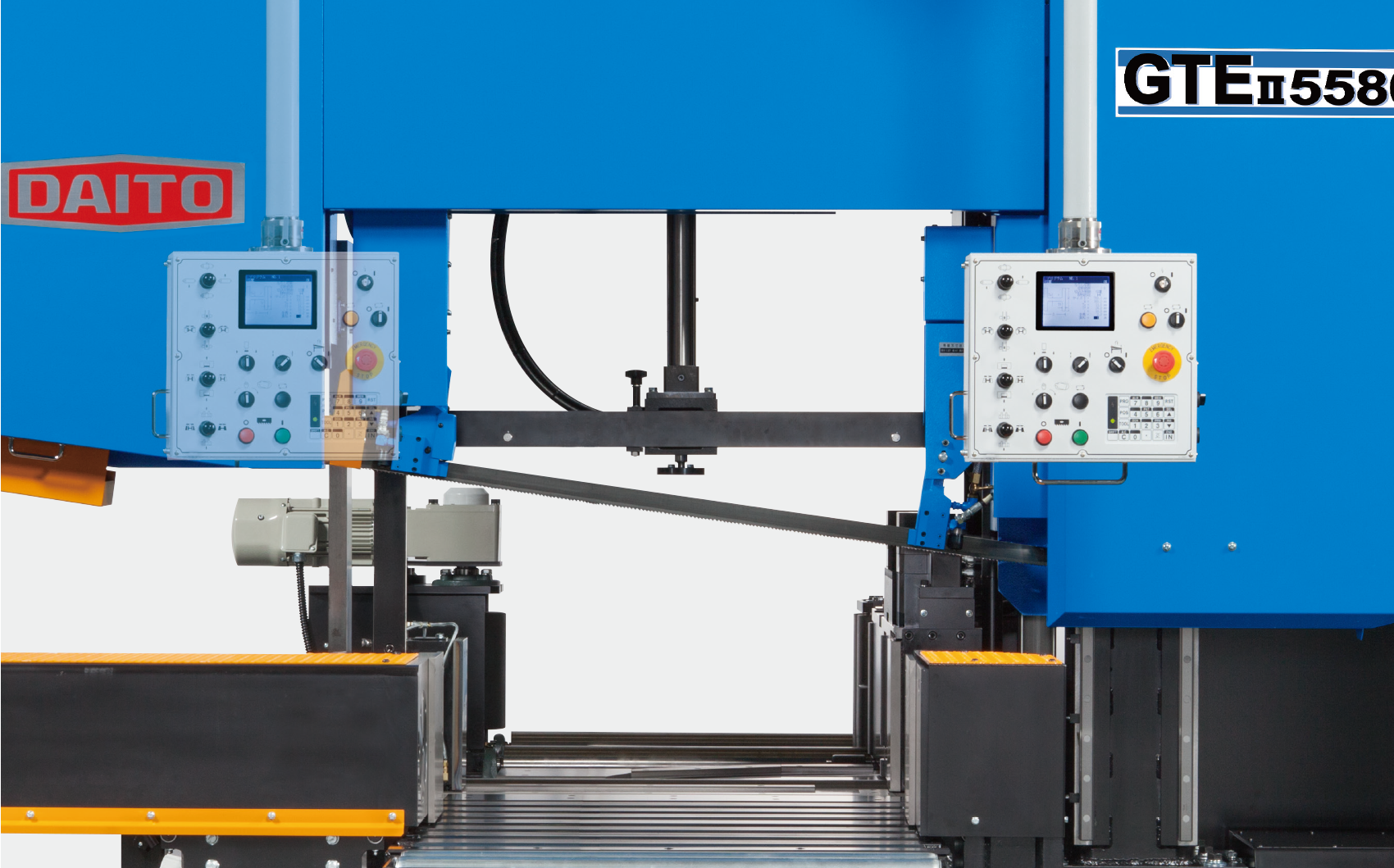

SAW FRAME LINEAR GUIDES

The saw frame goes up and down on linear guides reducing friction for more smooth and accurate blade feeding.

VERTICAL VIS

The vertical vise hydraulically clamps wide / bundled workpiece to prevent vibrations and blade failures.

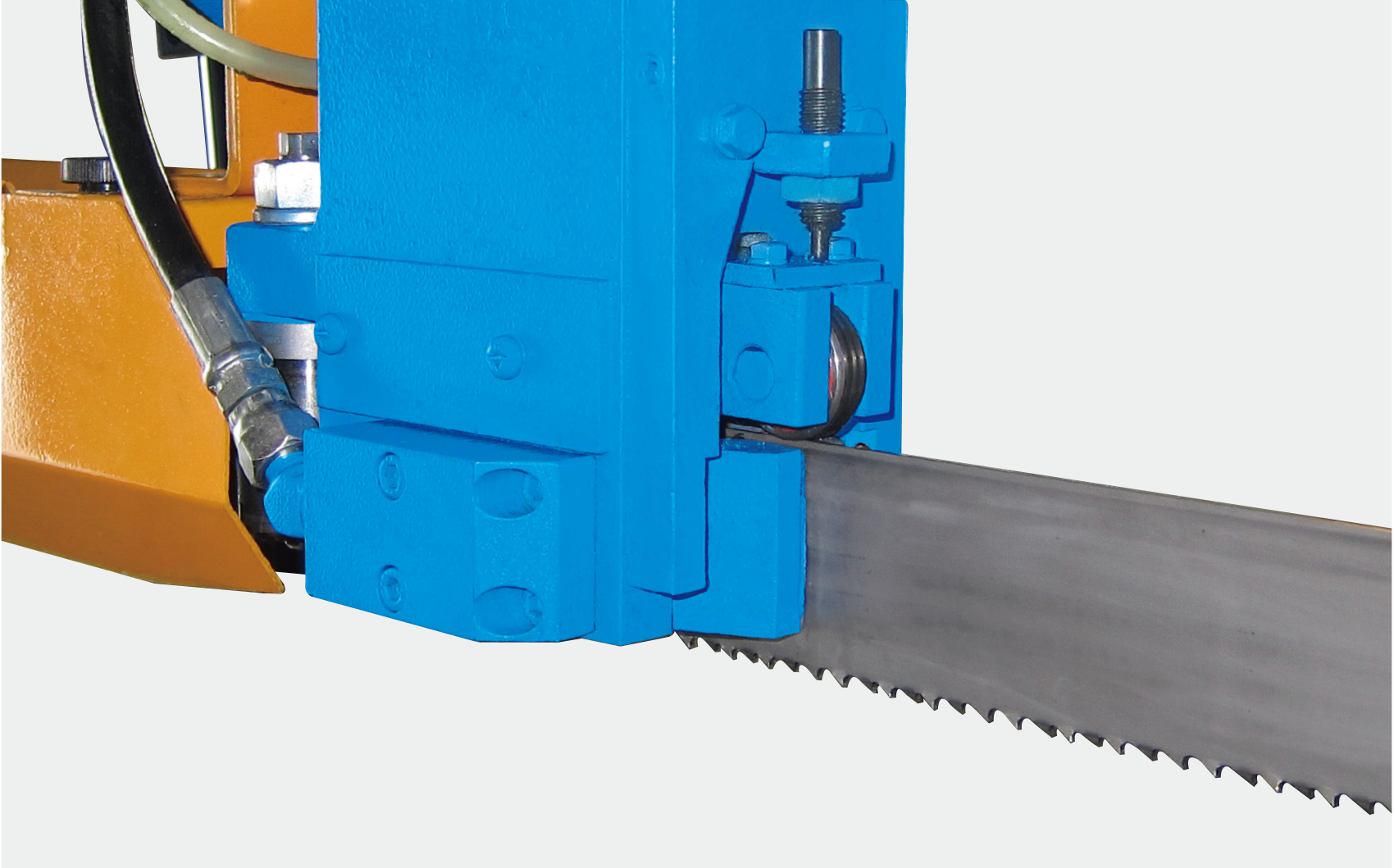

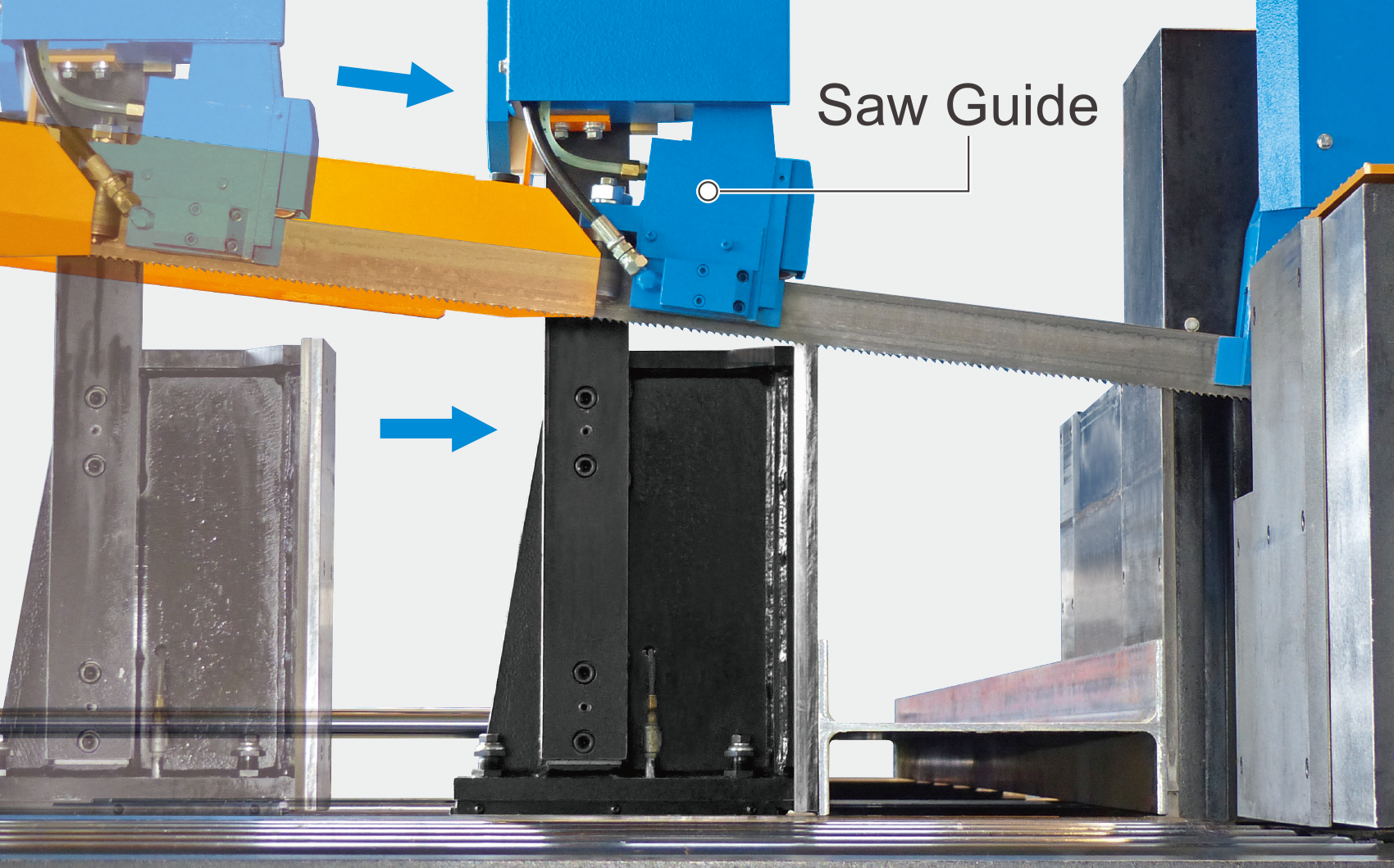

SAW GUIDE LINKED WITH VISE

Being linked with the vise, the left side saw guide is always close to the workpiece and the insert tips are hydraulically loaded for the best blade conditions.

WIDE CUTTING CAPACIT

From 2inch to 31 3/8inch wide workpiece can be clamped and cut.

SEMI DRY CUT (MIST SPRAY COOLANT)

In addition to conventional coolant flow, the mist cutting fluid applicator is included as a regular device. The job productivity is improved.

CLEAR SHADOW LINE

The cutting position is projected by the strong LED; the shadow is even clear in a bright working environment to make work positioning easy.

PENDANT OPERATION PANEL

The pendant mounted operation panel can be easily swung to either side of the machine for easy setup and operation.

CUTTING OPTIMIZATION

The cutting conditions are automatically controlled with CNC and the conditions details are displayed on the screen.

The vise pressure can be adjusted for thin wall material.

The laser beam helps to position workpiece when a markings are made on the left flange.

Roller tables are to be placed on the infeed and outfeed side of the machine. The tables come with 3,5,7,10 or 20 rollers per table depending on jobs.

The powered roller is linked with a roller table; lifts up workpiece by hydraulics and feed it to the machine driven by the motor.

The workpiece is pushed against the vertical rollers for precise alignment.

The traverse carts lift up and traverse workpiece to the conveyor lines.

From each machine to total automation, contact us freely.

9:00~17:00: phone available

847-437-6788(Head Sales Office)