BAND SAWING MACHINE

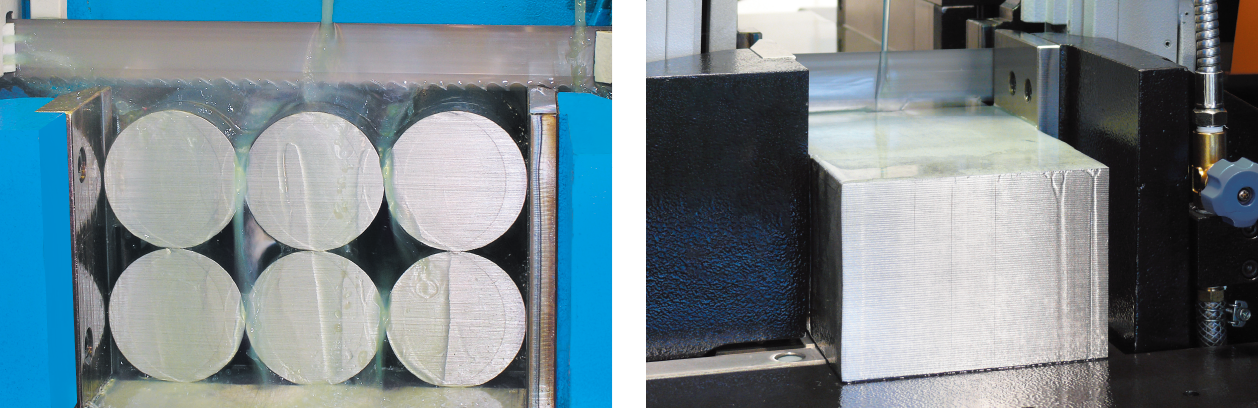

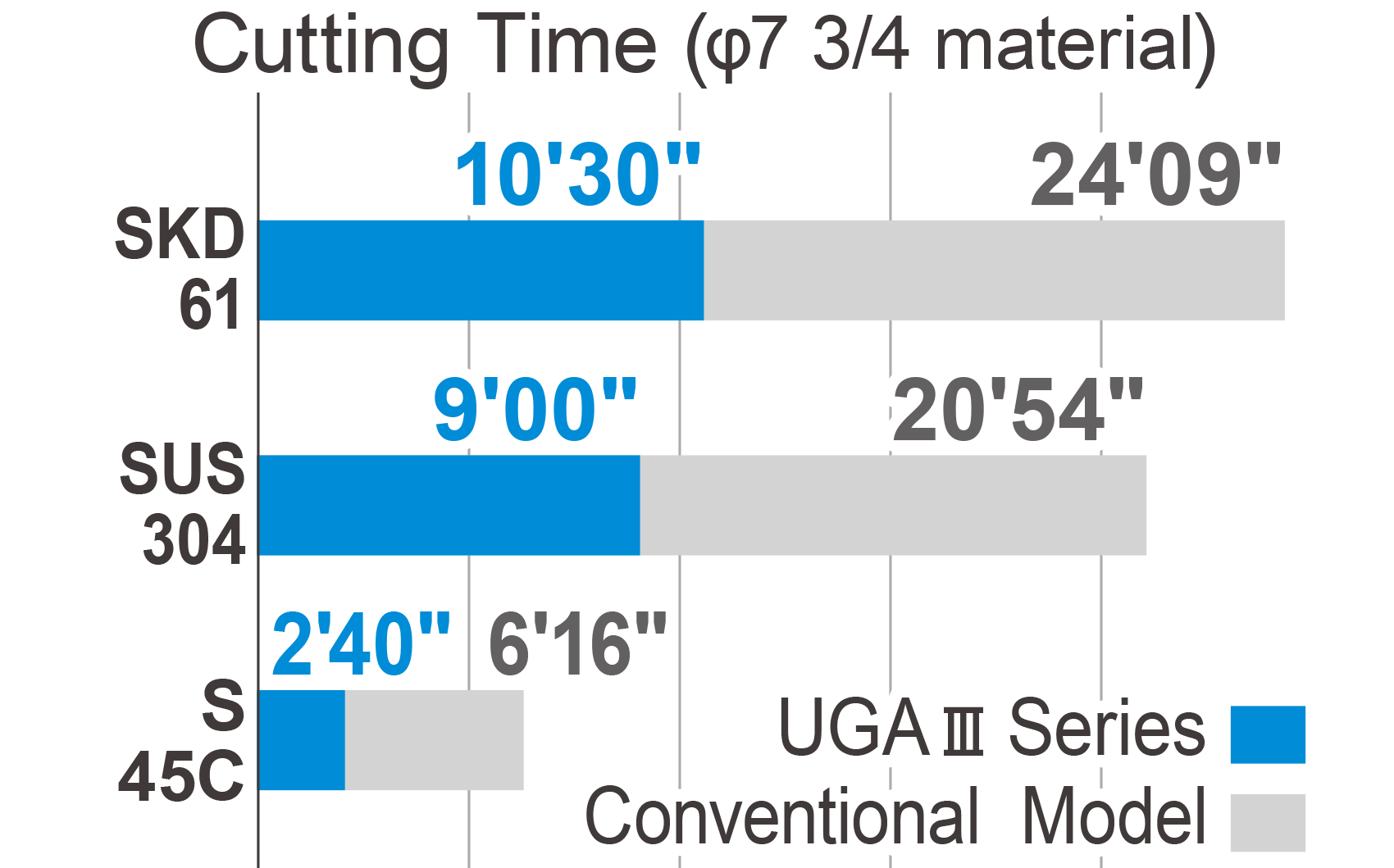

The rigid construction has doubled the cutting speed compared with conventional machines.

| product name | UGA260Ⅲ | UGA330Ⅲ | |

|---|---|---|---|

| product photo |  |

|

|

| Max. Capacity(W×H) | 10 1/8" | 12 7/8" | |

| 10 1/8" | 12 7/8" | ||

| 11 3/4" × 10 1/8" | 12 7/8" × 12 7/8" | ||

| 11 3/4" × 5 7/8" | 12 1/2" × 6 1/4" | ||

| Overall Dimentions (W×D×H) |

74 7/8" × 81 3/4" × 70 1/8" | 88 5/8" × 85 7/8" × 79 1/4" | |

| Machine Weight | 3,969 lbs | 5,843 lbs | |

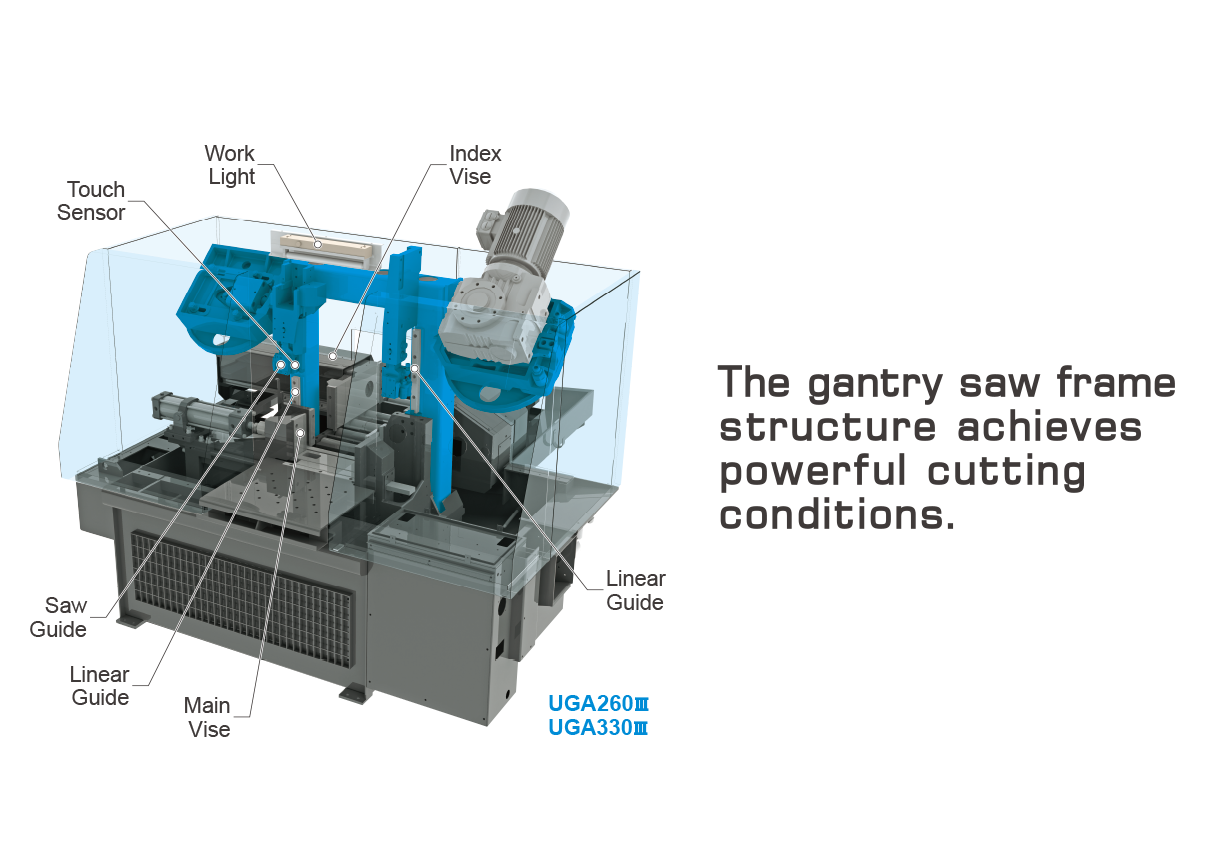

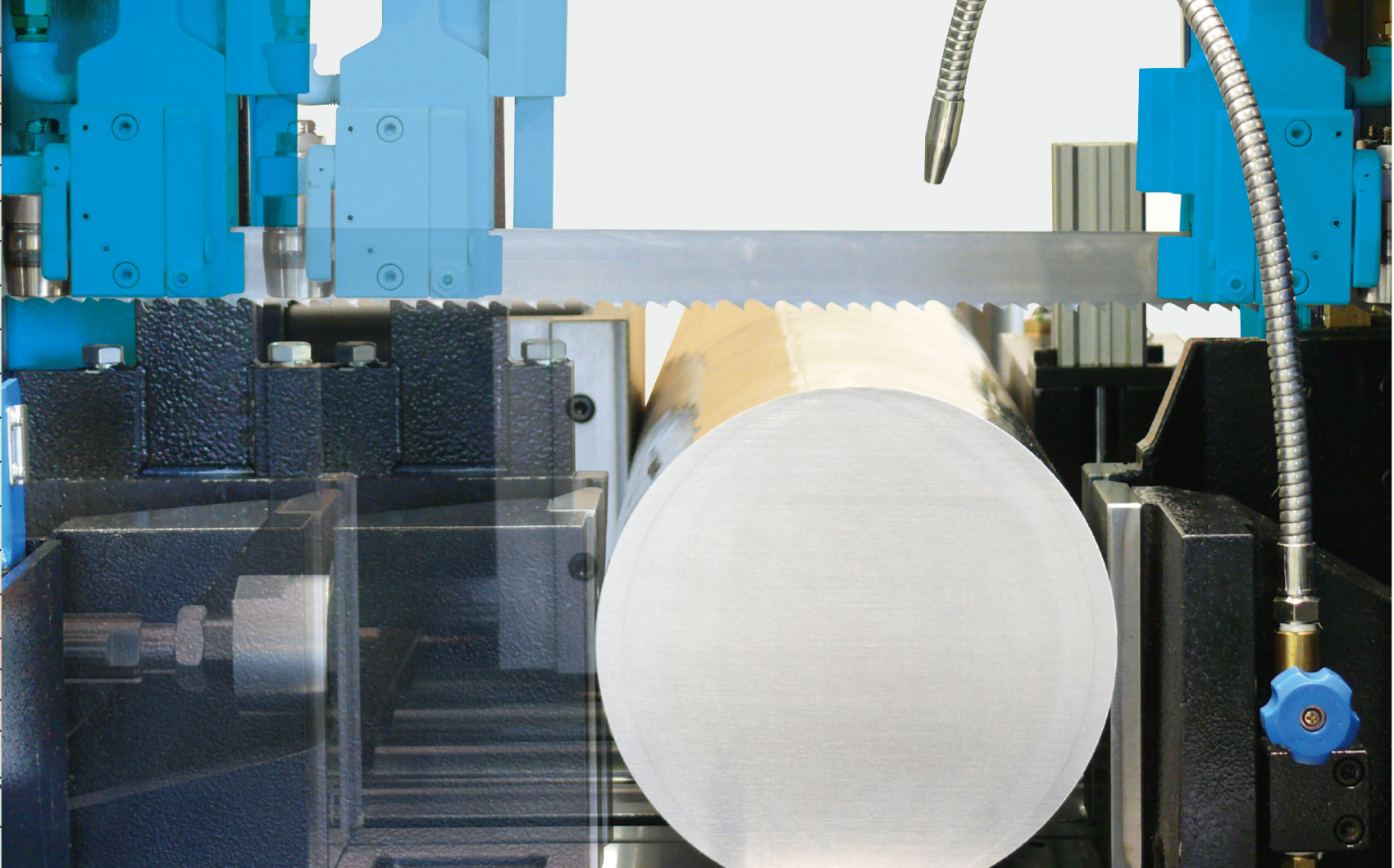

The UGAⅢ series adopts a rational design portal structure of the saw frame to increase the rigidity that was lacking in conventional machines. By bringing the linear guides closer to the saw blade, the cutting process can be controlled more accurately and forcefully, realizing higher speeds when cutting and beautifully cut surfaces.

HIGH PRODUCTION MACHINE

The UGA Ⅲ series have doubled the cutting speed of conventional machines with an optimized feed rate by the amplifying valve.

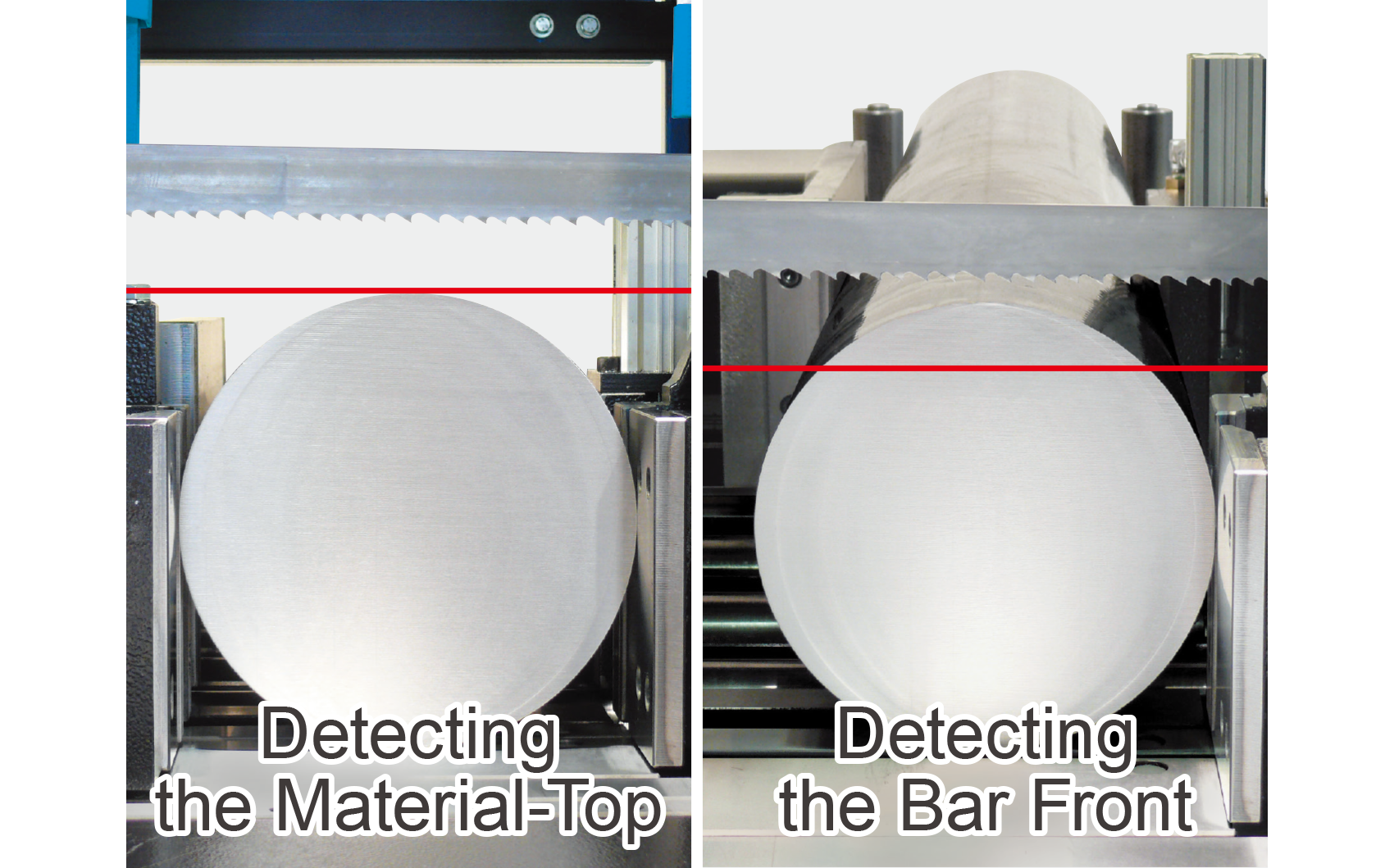

BAR FRONT/TOP DETECTOR

In auto cycle, the first cut is made without manual positioning by detecting the bar front/top with the laser beam.

BACK GAUGE FUNCTION

By inputting the required dimensions and positioning the tip of the feed vise as a back gauge, it is possible to cut out products with a length of 2 7/8 to 22 3/8 inch.

LINKED SAW GUIDE

The saw guide linked with the vise is always close to the workpiece, which ensures optimal cutting conditions.

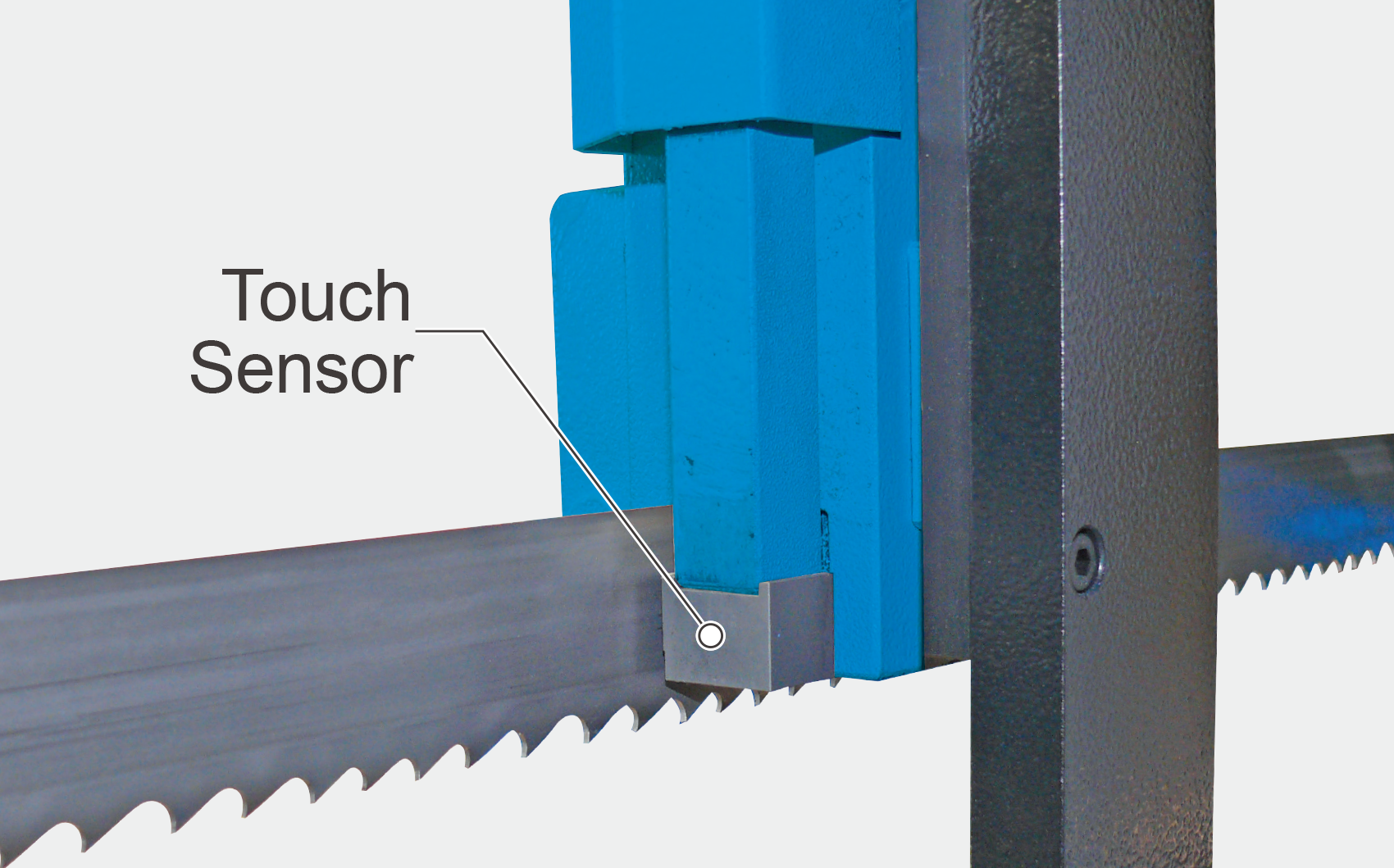

BLADE DEVIATION DETECTOR

The blade deviation detector monitors the blade for any minor deviation to halt the machine during cutting.

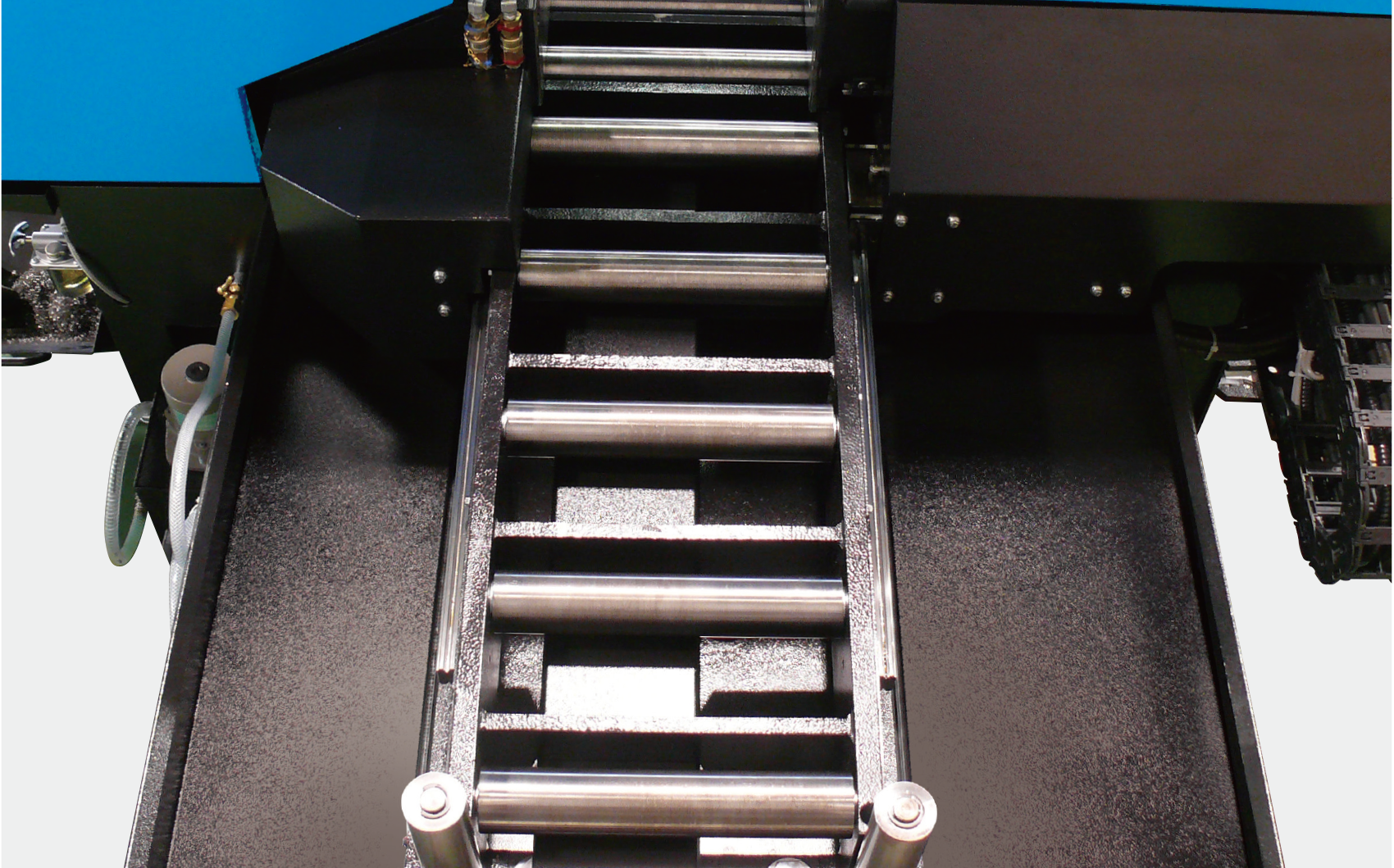

INDEXING TABLE WITH ROLLERS

The material is smoothly fed on the index roller table that is designed to withstand the heaviest of material.

The wide vertical vises are adjustment-free. The bumpy bundle is evenly absorbed by rubber pads to clamp firmly.

The vise pressure can be adjusted for thin wall material.

Clean cutting environment is enabled with the mist applicator which sprays cutting f luid to saw blade edges. An air source needed.

Contact short workpiece to the mounted fixture. Two fixtures available for large or small material.

The operation panel can be placed on the left side of the machine.

While the machine is running, the winker lights up.

From each machine to total automation, contact us freely.

9:00~17:00: phone available

847-437-6788(Head Sales Office)