BAND SAWING MACHINE

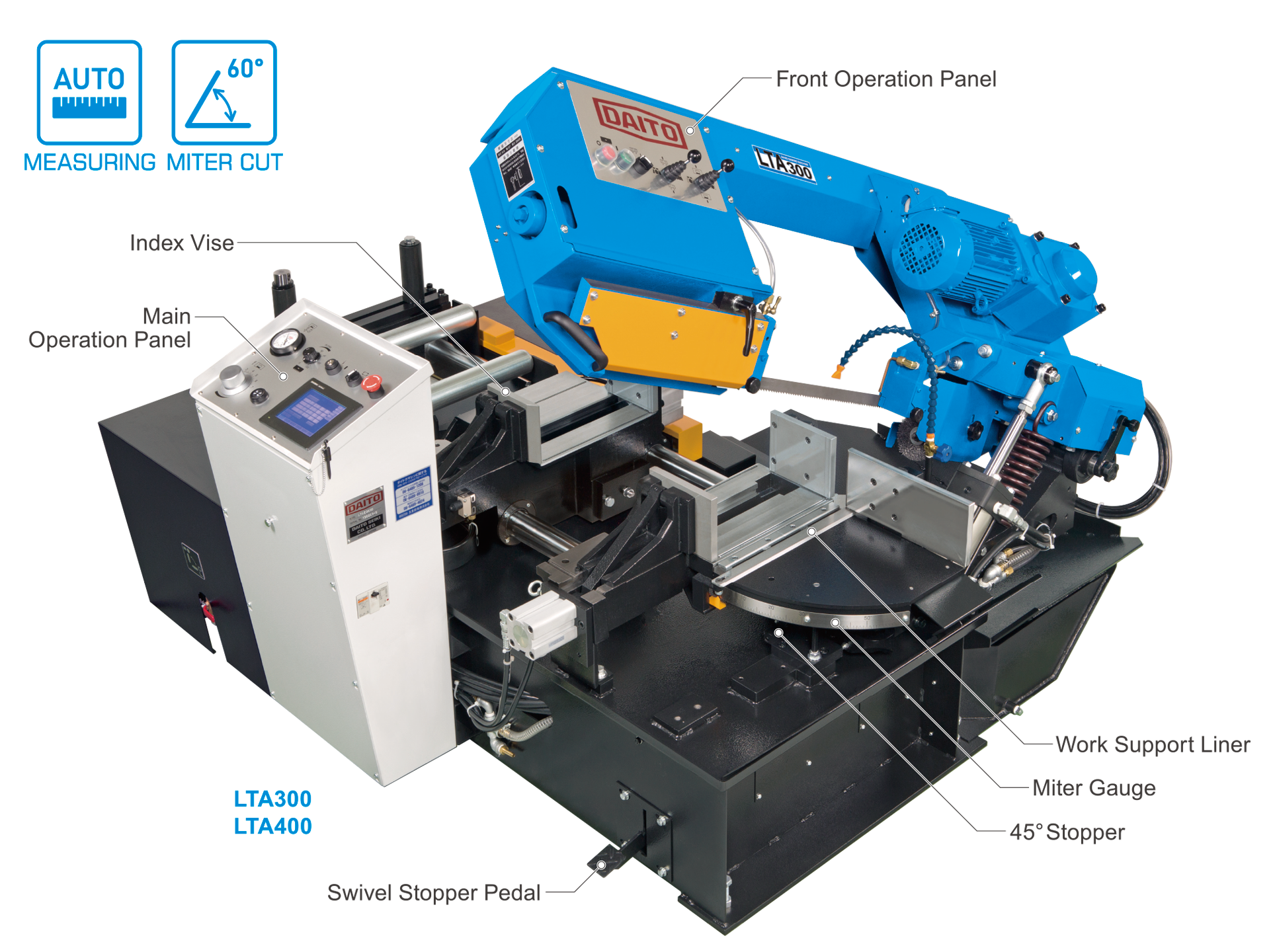

Miter cut up to 60 degree and automatic indexing machine for limited floor space.

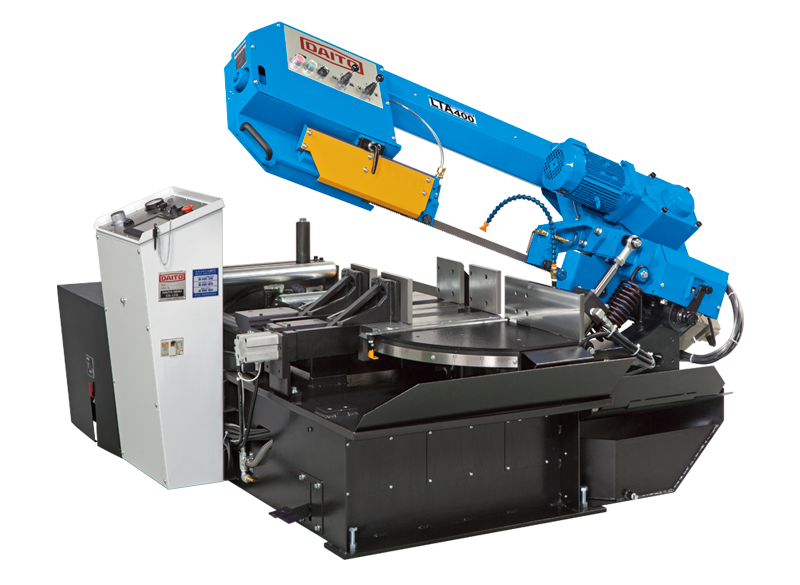

| product name | LTA300 | LTA400 | |

|---|---|---|---|

| product photo |  |

|

|

| Max. Capacity(W×H) |

10 1/8" |

10 1/8" | |

| 10 1/8" | 10 1/8" | ||

| 11 3/4" × 10 1/8" | 15 5/8" × 10 1/8" | ||

| 11 3/4" × 5 1/2" | 15 5/8" × 5 1/2" | ||

| Overall Dimentions (W×D×H) |

66 1/8" × 74 7/8" ×62 1/2" | 70 3/8" × 78 5/8" ×64 7/8" | |

| Machine Weight | 2,315 lbs | 2,426 lbs | |

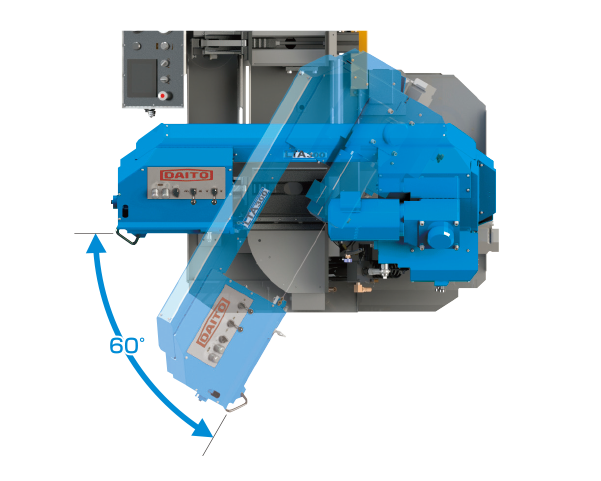

The LT・LTA series of DAITO is available to cut from 0° up to 60°.

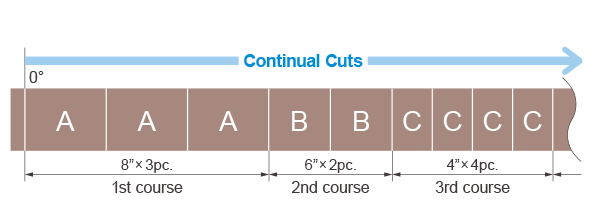

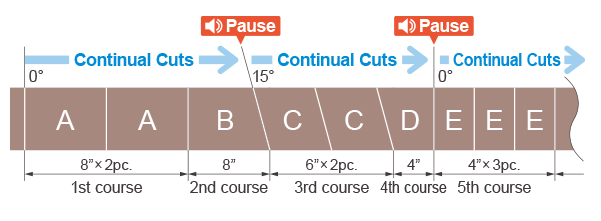

■CONTINUAL RIGHT ANGLE CUTS

For right angle cuts only, cut and indexing repeat without pauses.

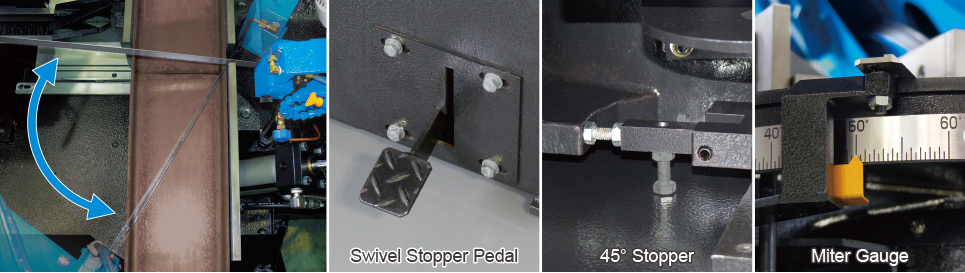

■OCCASIONAL MITER CUTS

For each miter cut, the run stops with alarm for manual swiveling. The miter cut kerf is calculated automatically.

For miter cuts, unlock the pedal and swivel the saw frame manually as far as it goes; 60° & 45°stoppers are available. Then lock the pedal to complete the setup.

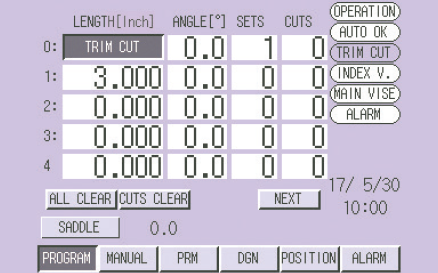

OPERATION PANEL

The main operation panel with its simple-to-use controls is located to the left of the machine.

EASY PROGRAM ENTRY

The LCD touch panel accepts cut length & cut piece.

FLOATING INDEX VISE FEED

Since the index vise floats to clamp slightly crooked material, the indexing is always smooth and accurate.

STABLE WORK SUPPORT

The material support liner follows the saw frame for optimum support in all angles to minimize burrs.

FRONT OPERATION PANEL

The frequently used switches for the operation of saw blade, saw frame and main/index vise are mounted in front.

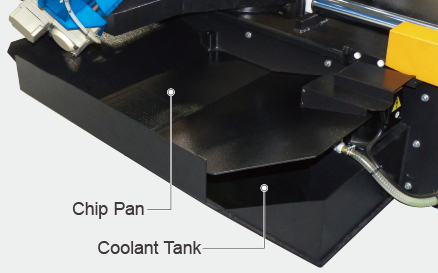

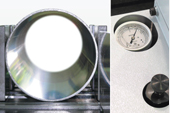

LARGE SIZE COOLANT TANK & CHIP PAN

The coolant tank capacity is 14 gallon with a large chip pan covering the tank.

EASY BLADE CHANGE

The saw wheel cover is hinged to saw frame to change saw blades easily.

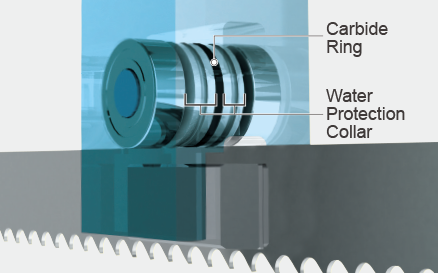

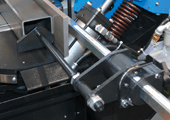

CARBIDE BACK-UP ROLLER

The carbide back-up roller placed between bearings which are isolated from cutting fluid assures long life of the equipment.

INVERTER VARIABLE SPEEDER

In accordance with material, the blade speed is adjustable even when running.

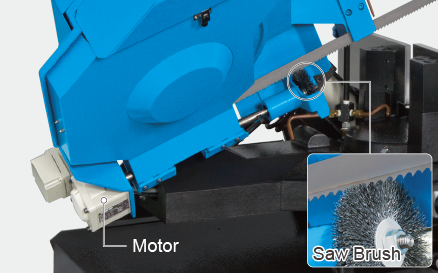

SAW BRUSH MOTOR

The independent brush motor removes saw chips thoroughly.

The wide vertical vises are adjustment-free. The bumpy bundle is evenly absorbed by rubber pads to clamp firmly.

Clean cutting environment is enabled with the mist applicator which sprays cutting fluid to saw blade edges. An air source needed.

Frequently used angles can be easily set and adjusted to position with the use of the angle stopper.

The vise pressure can be adjusted for thin wall material.

The length stopper makes continual manual cuts of equal length quickly and easily.

The bright LED work light projects the saw blade shadow clearly for precise manual positioning.

From each machine to total automation, contact us freely.

9:00~17:00: phone available

847-437-6788(Head Sales Office)