| Product Name |

DB500 |

|

|---|---|---|

| Product Photo |  |

|

|

Max. Capacity(W×H) |

- | |

| - | ||

| 20" × 12" | ||

| - | ||

| Overall Dimentions(W×D×H) | - | |

| Machine Weight | - | |

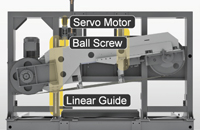

Servo controlled cutting feed rate

The servo-motor-ball-screw feed method is not affected by temperature, unlike hydraulic method; always accurate and stable.

Feed Rate Depending on Cross-Section

Feed rate is adjusted by the servo motor faster or slower depending on the cross-section of the material for the most efficient cutting condition.

Mist Lubricant

Mist lubricant is sprayed to blade edges. Unlike watered cutting fluid, both workpiece and the machine are kept clean to improve productivly.

Automatic Tool Changer (ATC)

Each drill unit has a tool magazine which can store maximum 8 tools for holes of different diameters, tapping and marking. The tools are replaced automatically.(*All tools are optional except initial oil hole drills. Programming software DISⅡ is required for processing.)

Scribing

Lines and numbers can be scribed by the drill spindle with scribing bit. They are clearly marked on material surface and it saves time from marking by hand.

With Another Tools

In addition to drilling, tapping (U1/4-U5/8), marking and chamfering are available on the top/left/right side of workpiece. The optional bottom marking device is available.

Materials are supplied by hained suppliers and lift pushers.

The products are diverted to the product yard.

Daito's advanced control incorporates Windows and Daito's exclusive DIS software for the most advanced systems.

Product data is marked by either legible ink jet or scribing which is even identifiable after coating.

Programs are input previously at office; transferred via network or USB stick.

From each machine to total automation, contact us freely.

9:00~17:00: phone available

847-437-6788(Head Sales Office)