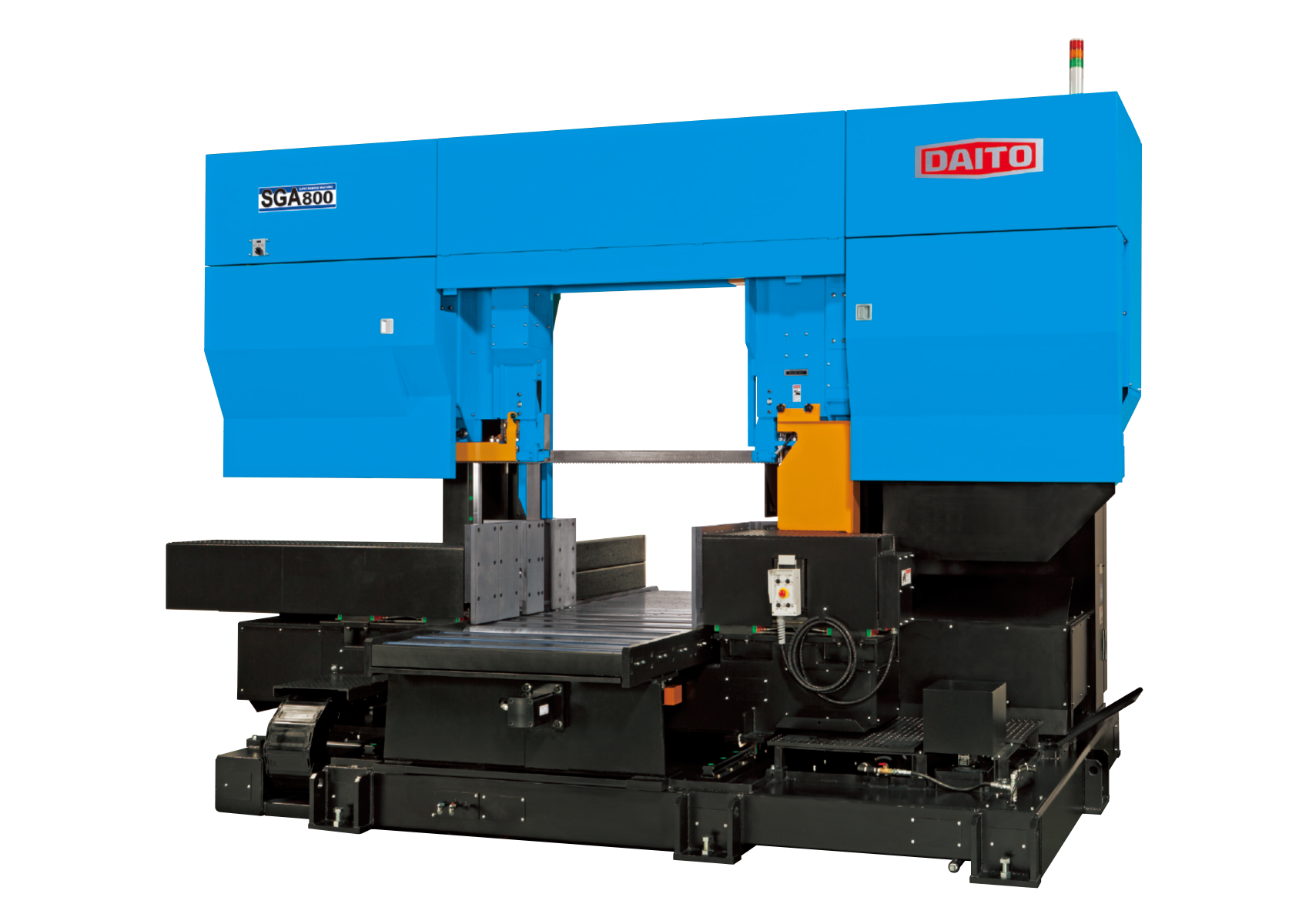

BAND SAWING MACHINE

DAITO’s SGA800 saw is targeted to cut alloy steels such as stainless steel, dice steel, nickel alloy and titanium alloy accurately with high speed. Improved cutting efficiency through precise infeed control. The status of each cut is monitored on the screen by the CNC. The usability is also greatly improved by a new operator interface. All together the SGA800 machine is highly rated for its speed of cut and machine usability.

| product name | SGA800 | |

|---|---|---|

| product photo |  |

|

| Max. Capacity(W×H) | 31 3/8" | |

| 31 3/8" | ||

| 39 1/4" × 31 3/8" | ||

| - | ||

| Overall Dimentions (W×D×H) |

184 7/8" × 97 7/8" × 138 3/4" | |

| Machine Weight | 26,059 lbs | |

DAITO’s SGA800 saw is targeted to cut alloy steels such as stainless steel, dice steel, nickel alloy and titanium alloy accurately with high speed. Improved cutting efficiency through precise infeed control. The status of each cut is monitored on the screen by the CNC. The usability is also greatly improved by a new operator interface. All together the SGA800 machine is highly rated for its speed of cut and machine usability.

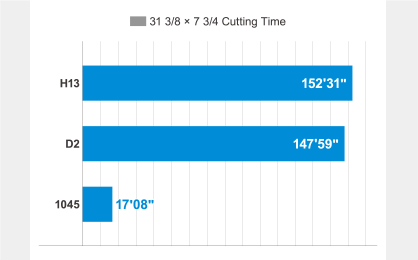

The new version of SGA800 has increased it’s cut speed by 10 percent due to a newly developed servo control system.

The new servo motor has more delicate response;The feed control is optimized further for both speed and tool life.

■EASY PROGRAM ENTRY FOR EVERYBODY

Select shape and material.* The size is measured by the machine automatically. The cutting conditions can be customized in accordance with customer’s needs; can differentiate cutting control freely.

*Profiles such as pipes needs thickness entry.

■OPERATOR INTERFACE

12 inch large panel for data entry and push buttons / joysticks for operation --- the integration of both enabled quick machine operation and quick data access.

■LIGHT EMITTING BUTTONS

The light emitting push buttons are for easy operation even at night. When automatic run setup is ready, the start button flickers.

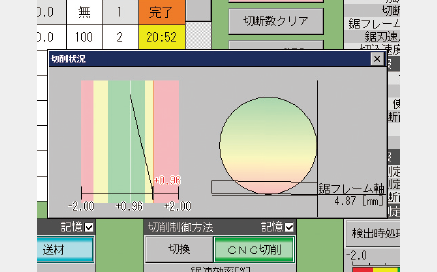

■VISUALIZED CUTTING STATUS

The saw blade position, crooked cut deviation of the cross-section is monitored real time. The visual interface shows everything at a glance.

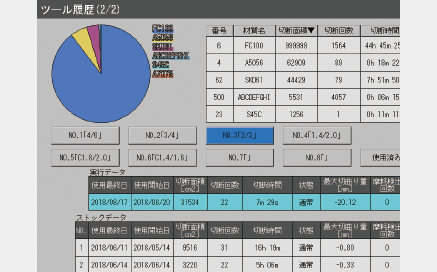

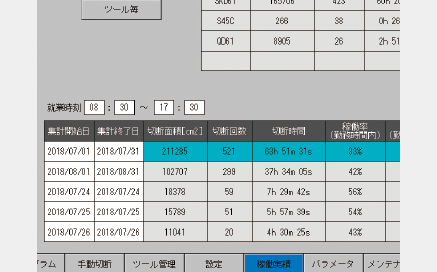

■TOOL MANAGEMENT

The records of each saw blade such as cumulative cutting time / area is shown for tool management.

■OUTPUT OF JOURNALS

The cutting records such as cumulative run time and cut time / area are output as daily / monthly journal data for your review.

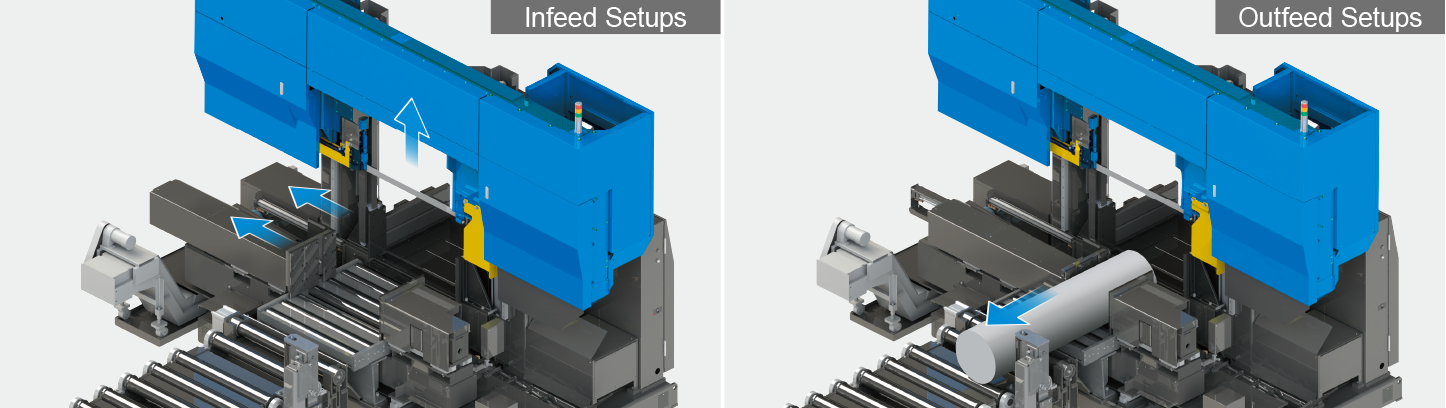

The work infeed setups such as saw frame raise and vises open; the work outfeed setup such as a remnant retraction --- are available just by pushing a button. The troublesome setup sequence is automated. All you need is just pushing a button.

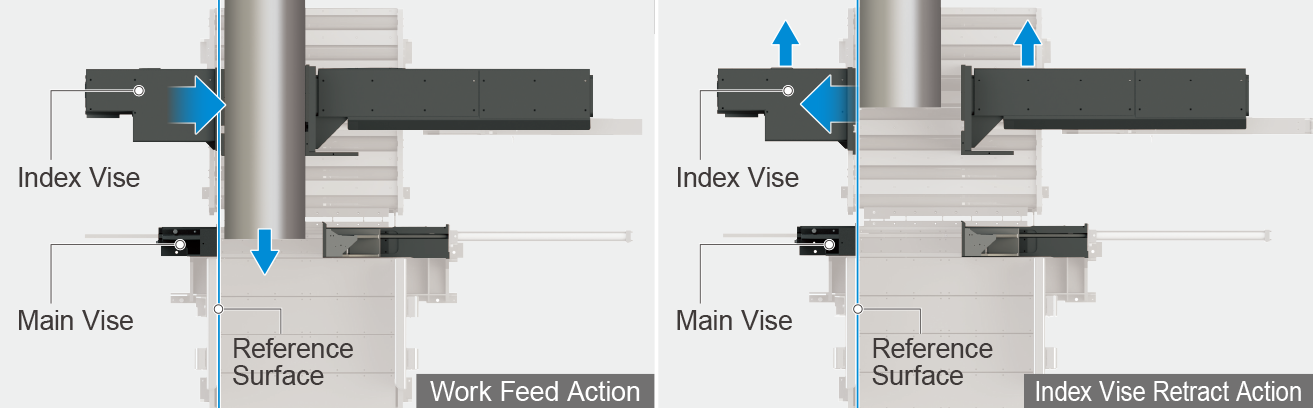

When indexing, the index saddle slightly shifts material aside to avoid scratching the surface by the vise, which is good for stainless /cold-finished steel bars.

AUTOMATIC START BY SENSOR

To start an auto cycle, the operator only needs to clamp the workpiece with the index vice. The will then machine detect the front surface and cut the initial piece to the exact length as programmed.

BACK GAUGE FUNCTION

The index vise can be also used as a back gauge for convenient accurate single cutting operations.

SUB OP. BUTTONS FOR WORK INFEED

Sub Operation Buttons are equipped for quick operation such as vise clamp or frame move.

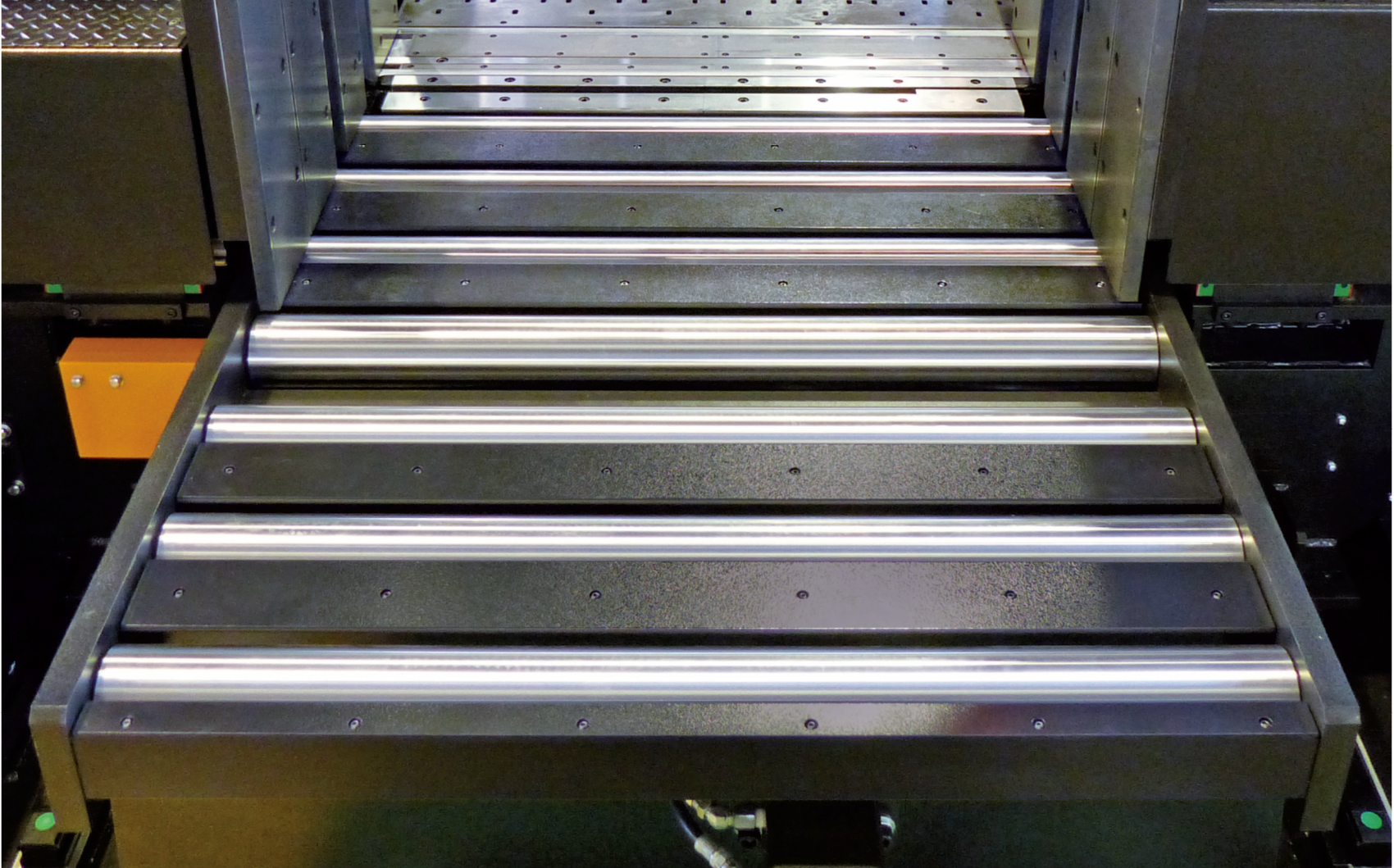

INDEXING TABLE WITH ROLLERS

The material is smoothly fed on the index roller table that is designed to withstand the heaviest of material.

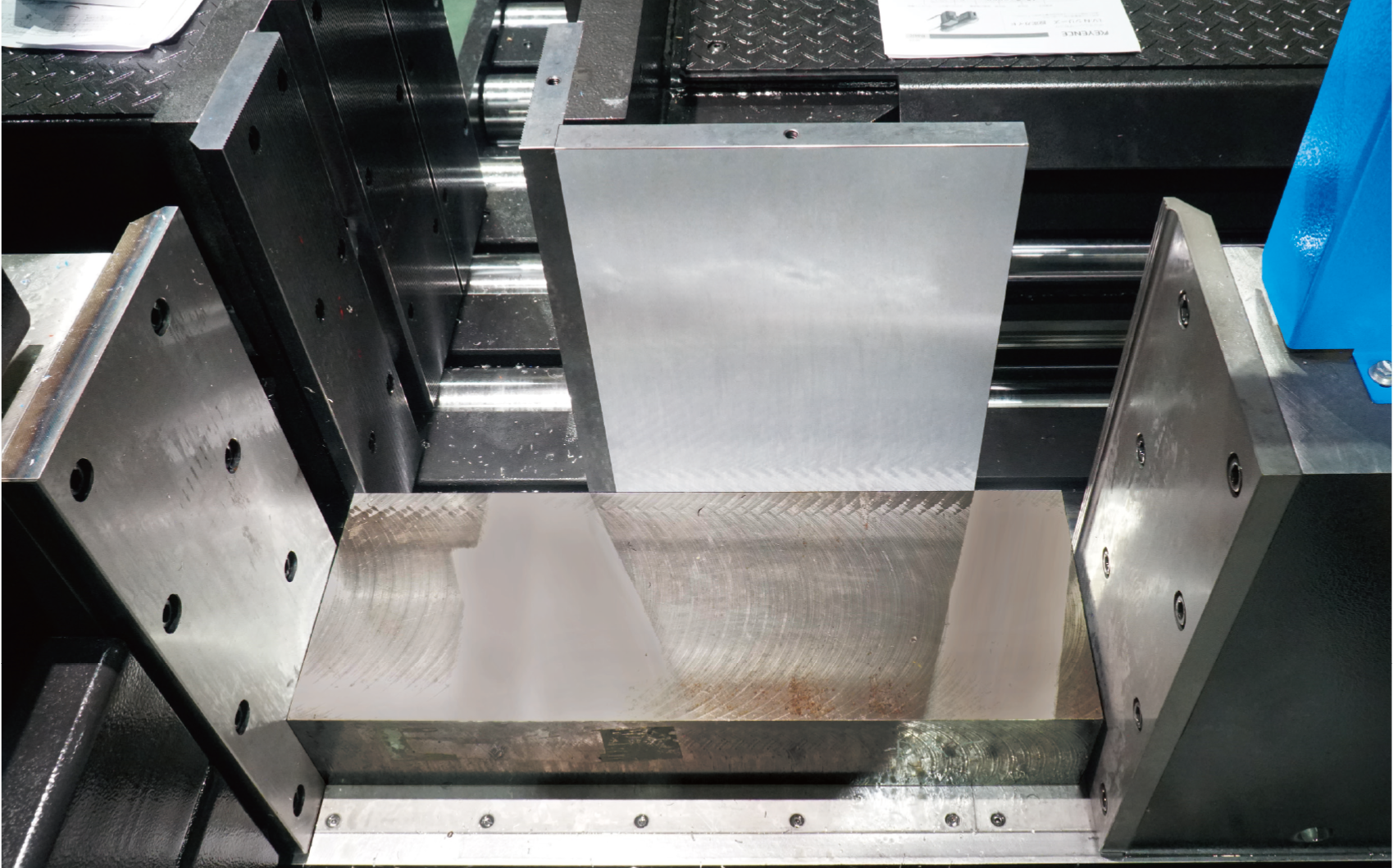

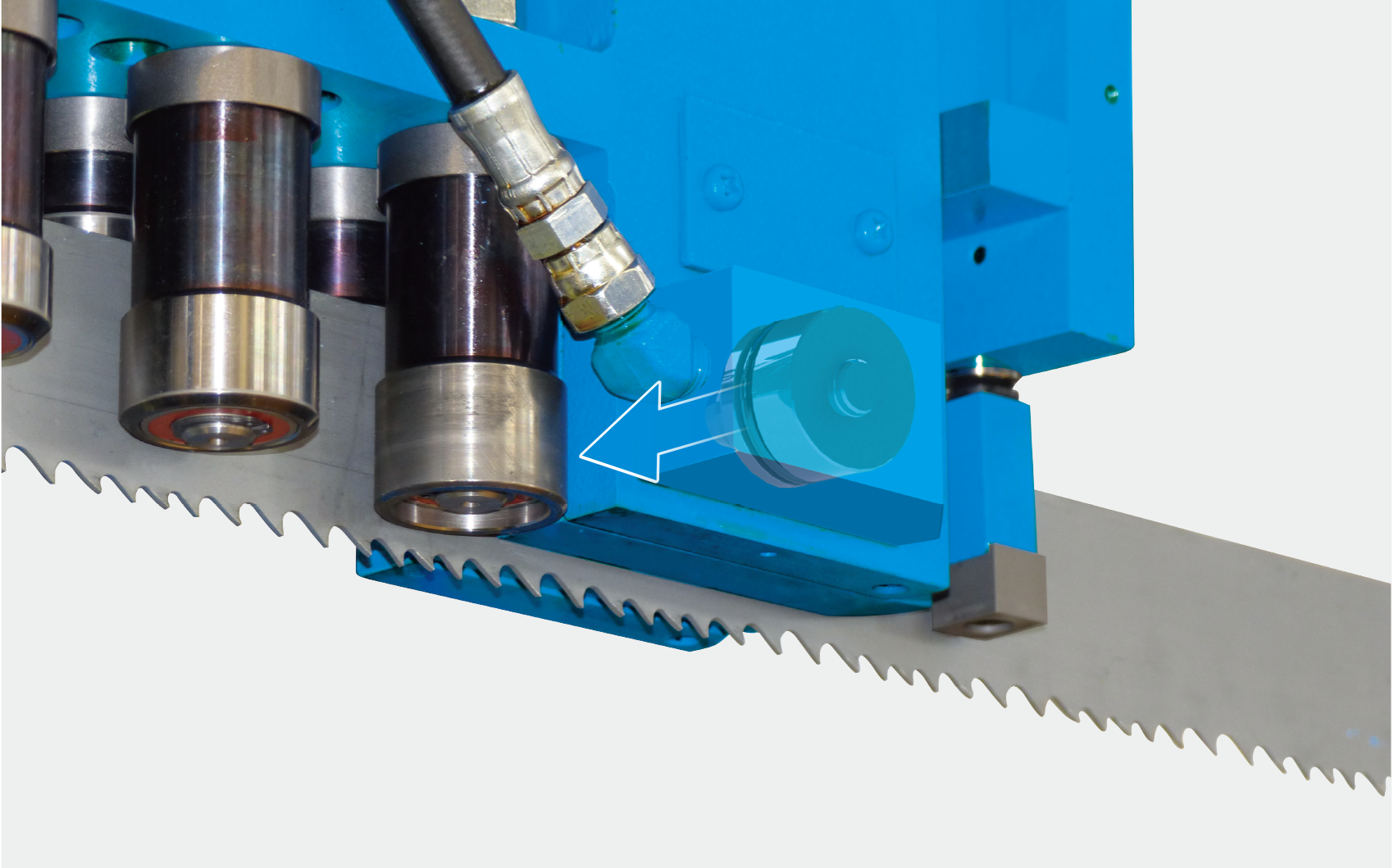

HYDRAULIC INSERT TIPS

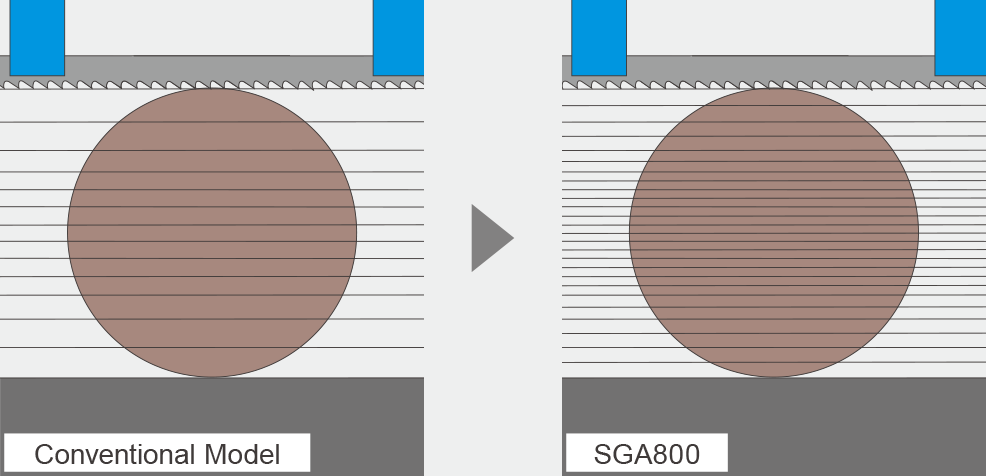

The guide insert tips are hydraulically clamped to the saw blade with the proper pressure to ensure an accurate and square cutting.

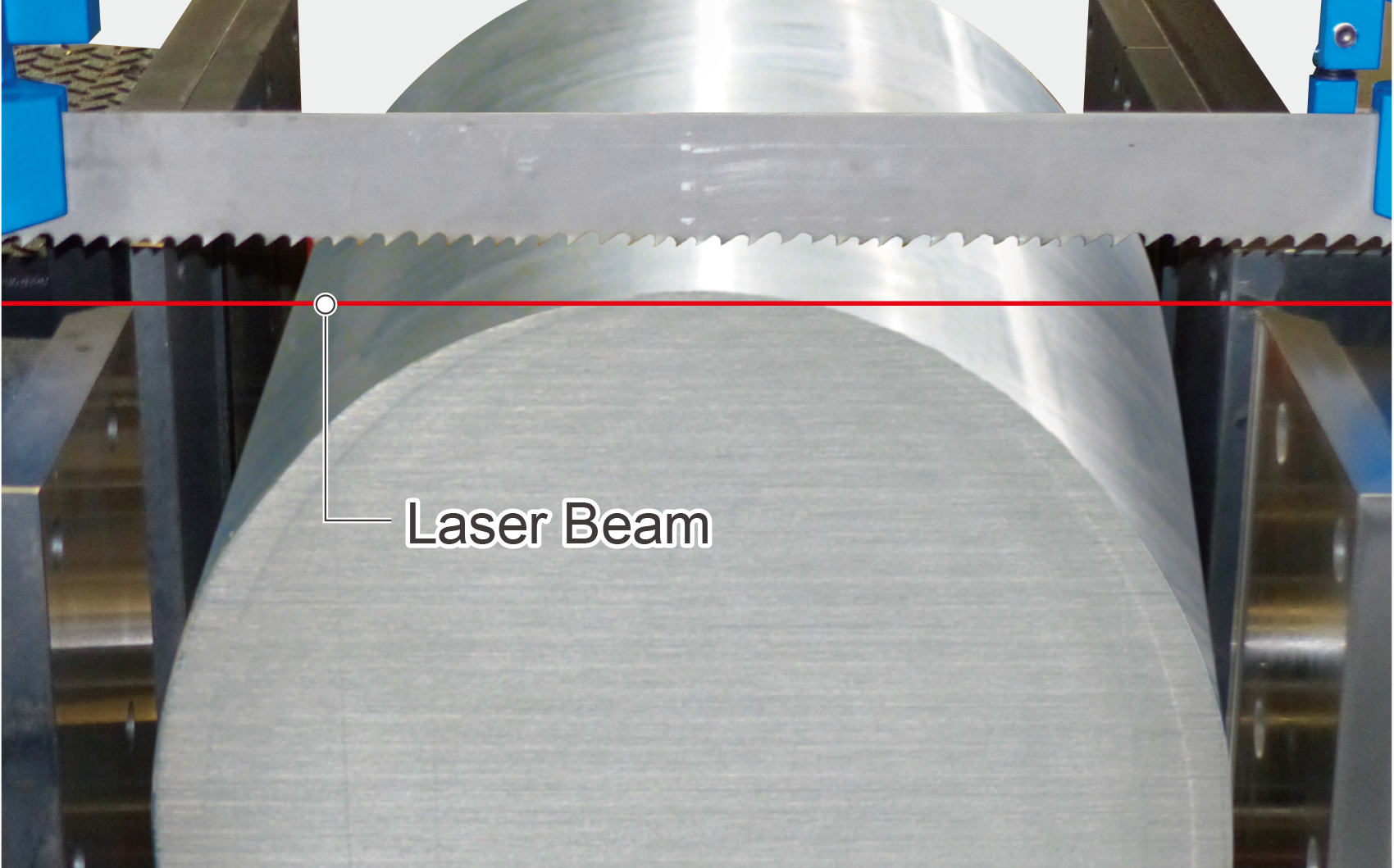

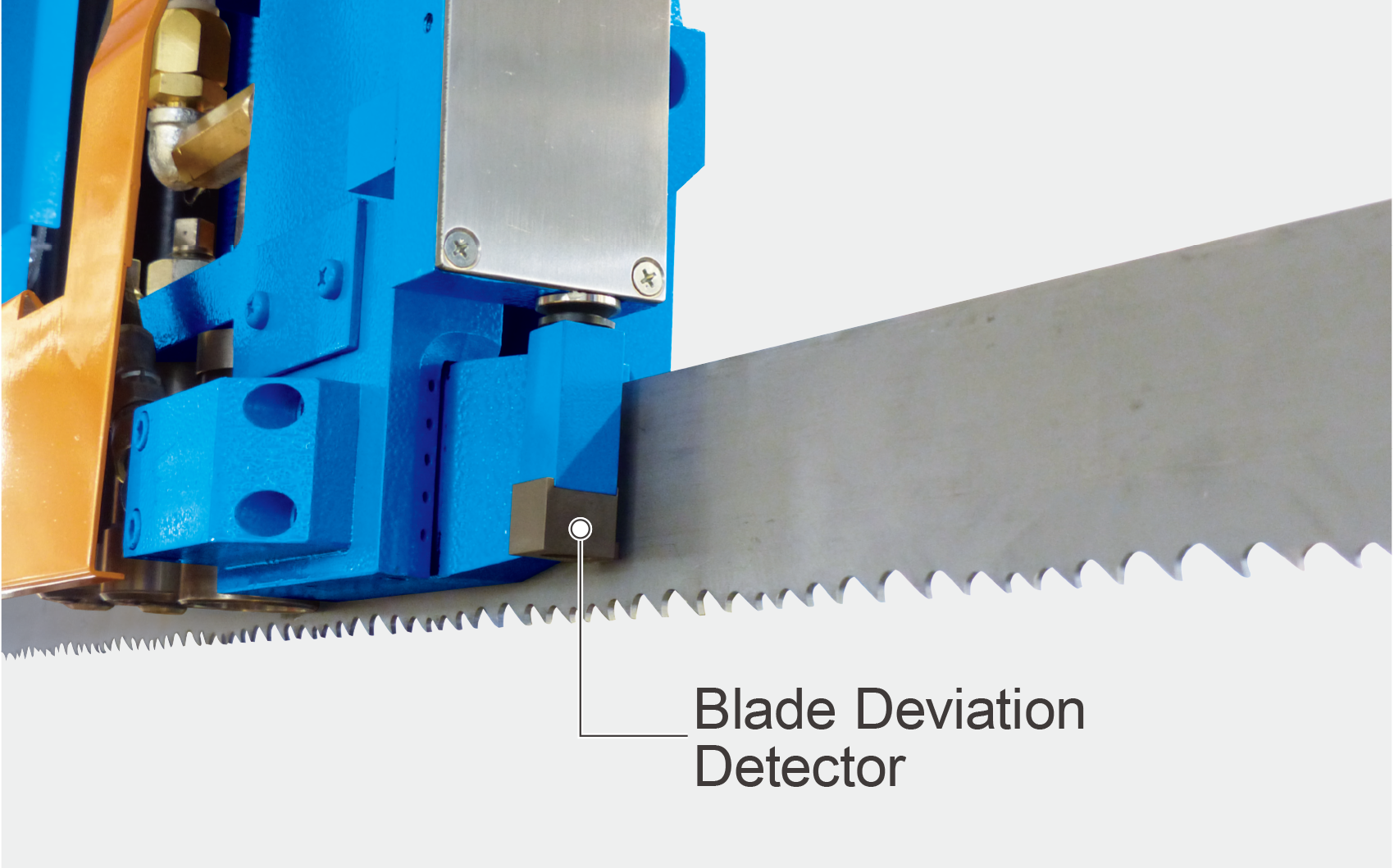

BLADE DEVIATION DETECTOR

This detector monitors the blade for any minor deviation during cutting and halts the machine if out of tolerance.

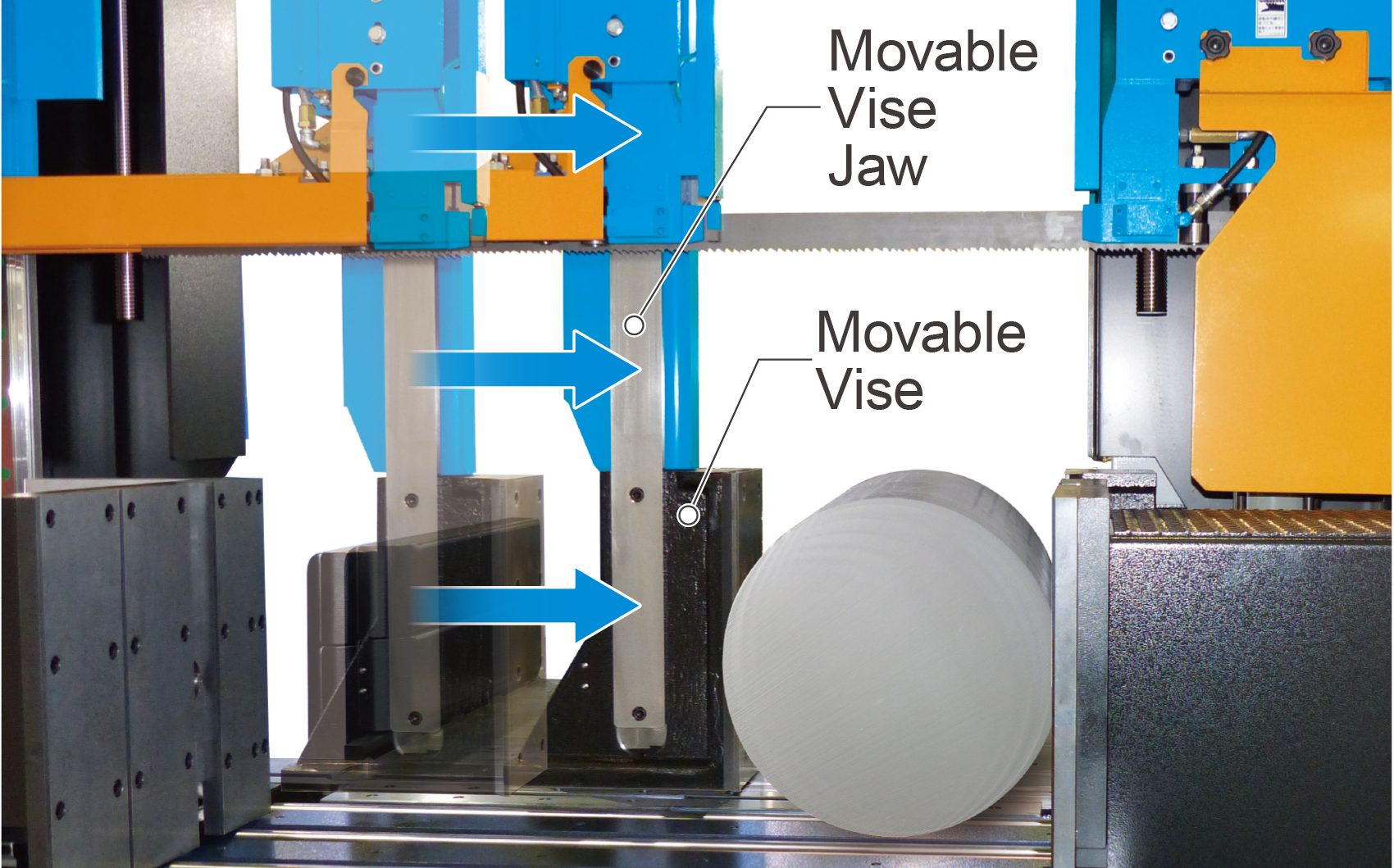

LINKED SAW GUIDE

The movable saw guide is linked with the movable vise jaw position to be as close to the work piece as possible. This ensures optimal cutting conditions.

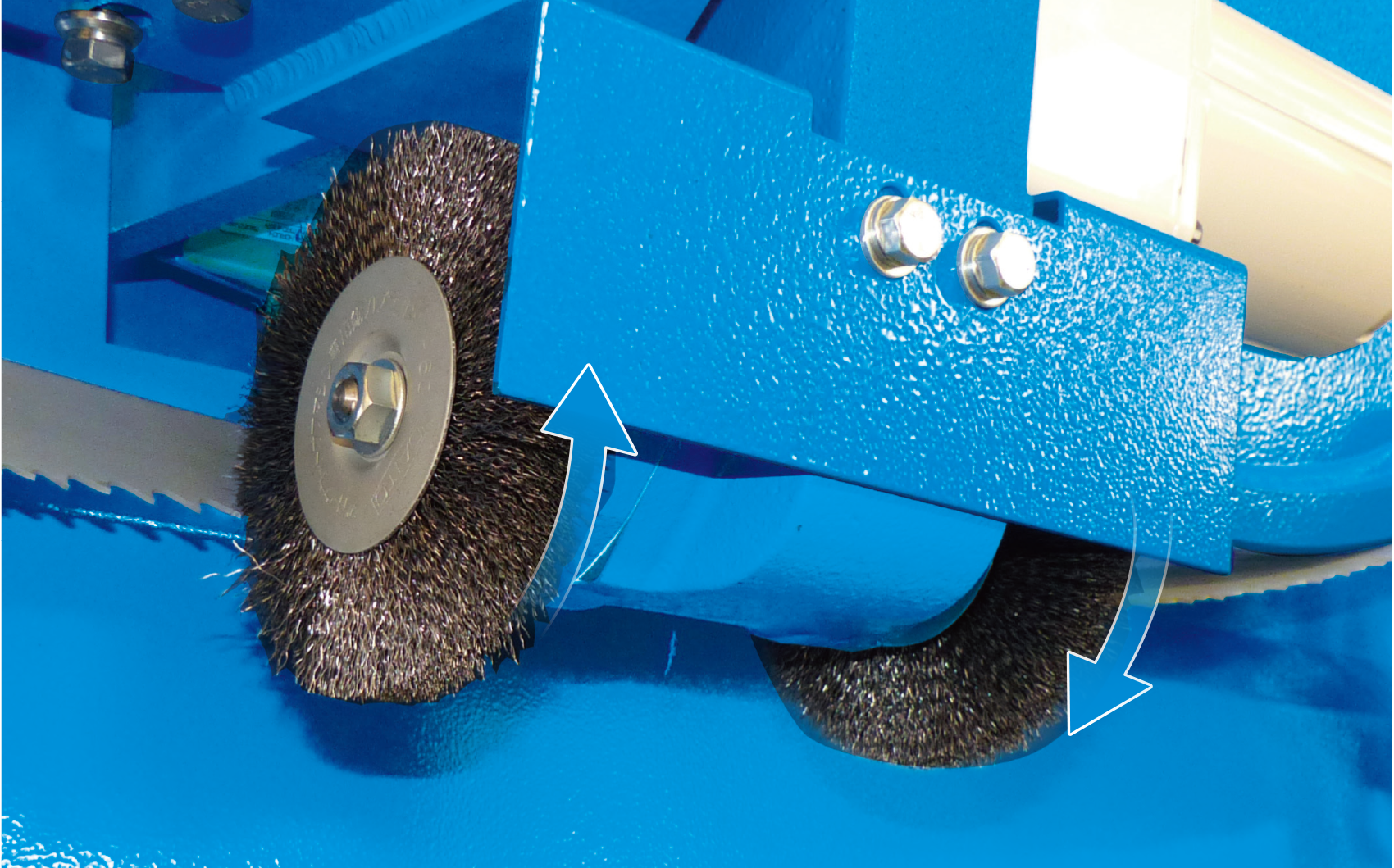

FORWARD-REVERSE TWIN BRUSHES

The twin saw brushes run mutually opposite way to wipe out saw chips thoroughly for accurate cuts and longer blade life.

From each machine to total automation, contact us freely.

9:00~17:00: phone available

847-437-6788(Head Sales Office)